Print Oxford fabric has become one of the most versatile and stylish textile materials in the global market. Known for its distinct weave pattern, durability, and ability to showcase vibrant printed designs, this fabric is widely used in fashion, home décor, bags, and even industrial applications. But what exactly makes Print Oxford fabric so unique? How is it made, and where can it be used most effectively? In this article, we’ll explore its origins, characteristics, printing methods, applications, and selection tips in detail.

1. What Is Print Oxford Fabric?

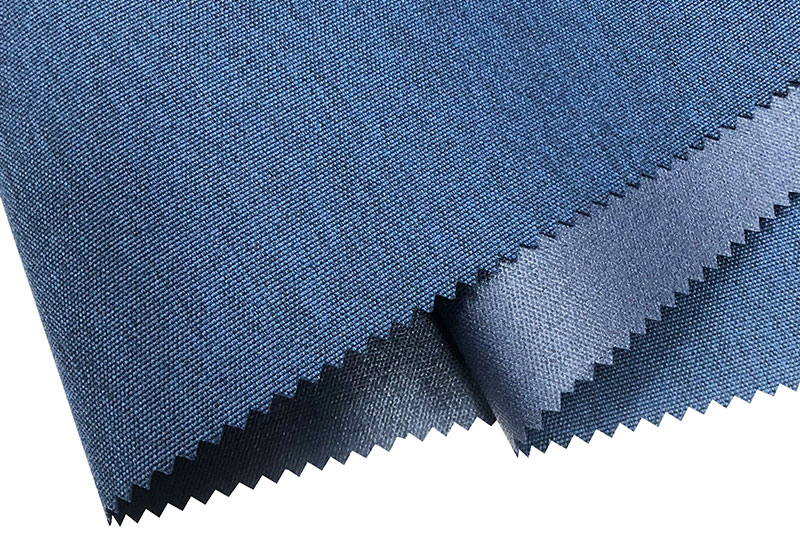

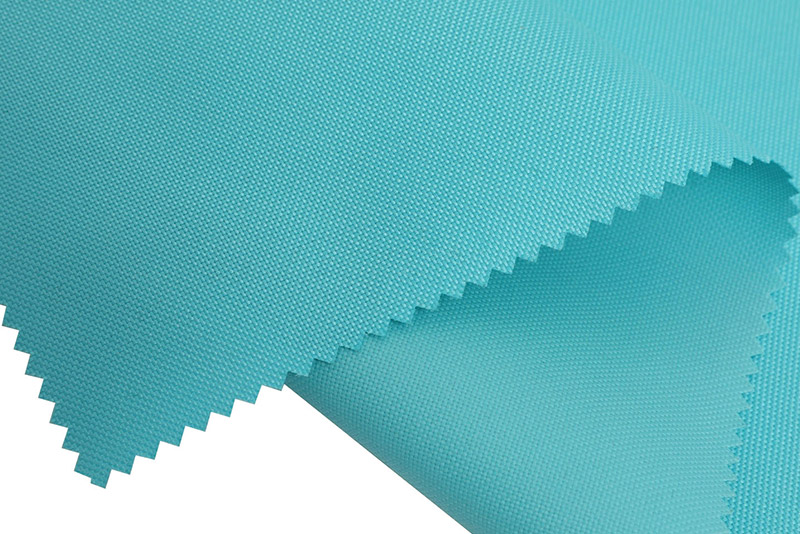

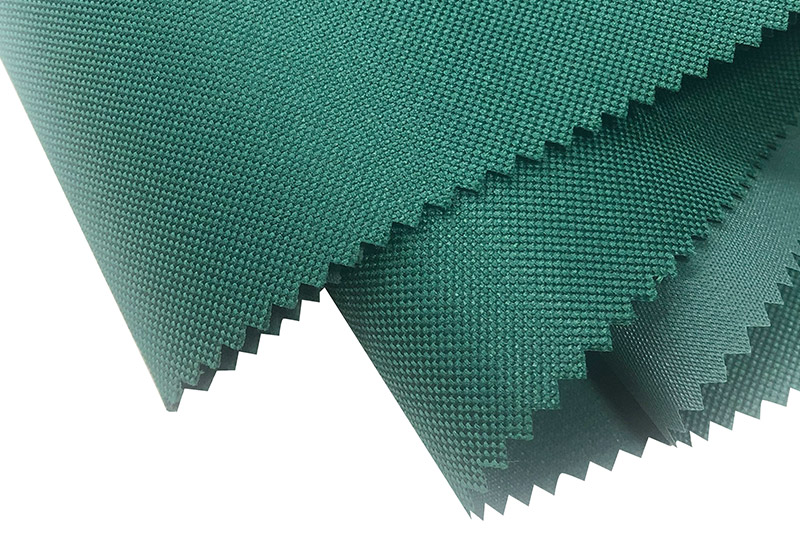

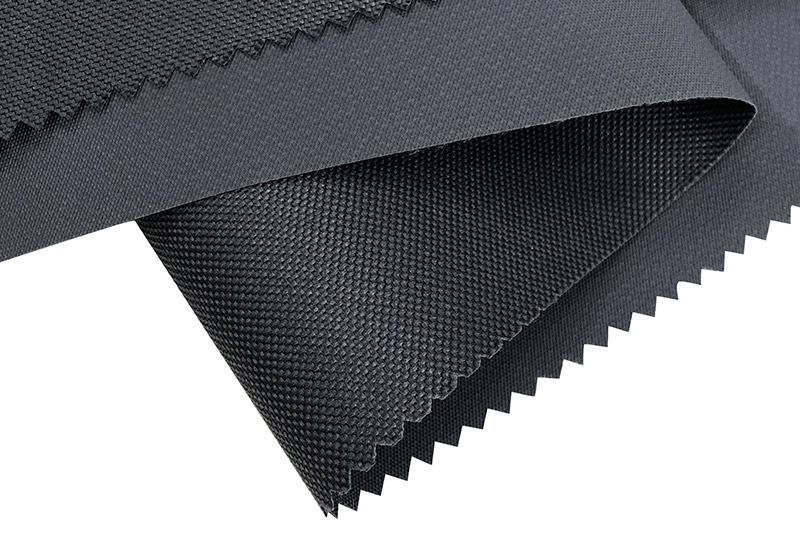

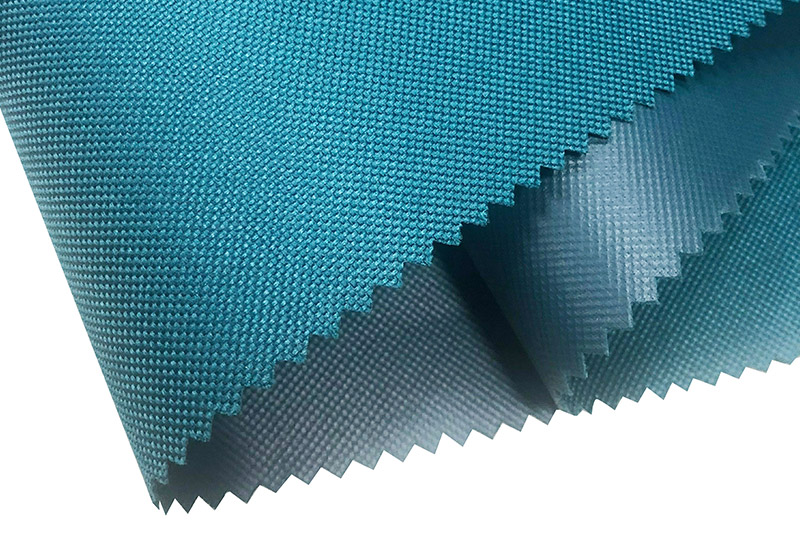

Oxford fabric is a woven textile, typically made from cotton, polyester, or blends, recognized for its basket-weave or plain-weave structure. The “Print” in Print Oxford fabric refers to the application of colorful patterns or images using various printing methods.

Unlike plain-dyed Oxford fabrics, printed Oxford fabrics are designed to combine visual appeal with functional performance, making them suitable for both fashion and heavy-duty purposes.

2. How Is Print Oxford Fabric Made?

The production process involves two main stages: fabric weaving and printing.

-

Weaving Stage

- Material Selection – Cotton for breathability, polyester for durability, or blends for balanced performance.

- Weaving – The Oxford weave (often basket weave) produces a soft yet strong fabric.

- Finishing – The fabric may be treated for water resistance, wrinkle resistance, or flame retardancy.

-

Printing Stage

- Screen Printing – For bold, durable patterns with high opacity.

- Digital Printing – For detailed, full-color designs and small batch production.

- Heat Transfer Printing – For quick application of vibrant images.

- Rotary Printing – For continuous patterns on long fabric rolls.

3. Key Features of Print Oxford Fabric

| Feature | Description | Benefit |

| Durability | Strong weave structure resists tearing and abrasion | Suitable for heavy use in bags, upholstery, and outdoor gear |

| Versatile Printing | Accepts multiple printing techniques | Allows for creative and customized designs |

| Water Resistance | Can be coated with PU or PVC | Ideal for raincoats, tents, and outdoor furniture |

| Breathability | Cotton blends maintain airflow | Comfortable for clothing and home textiles |

| Fade Resistance | Prints remain vibrant with proper treatment | Long-lasting visual appeal |

| Easy Maintenance | Machine washable and wrinkle-resistant | Convenient for daily use |

4. Applications of Print Oxford Fabric

-

Fashion and Apparel

- Casual shirts, dresses, jackets, and school uniforms.

- Printed Oxford fabrics are popular in custom-made fashion due to their ability to hold bright colors and patterns.

-

Bags and Accessories

- Backpacks, tote bags, cosmetic pouches, and travel gear.

- Oxford fabric’s strength supports heavy loads while prints enhance style.

-

Home Décor

- Curtains, cushion covers, tablecloths, and upholstery.

- Patterns can match interior design themes for a personalized look.

-

Outdoor and Sports Equipment

- Tents, picnic mats, camping chairs, and sports bags.

- Water-resistant coatings make it ideal for outdoor environments.

-

Promotional and Custom Products

- Company-branded merchandise, event giveaways, and team gear.

5. Printing Techniques for Oxford Fabric

-

Screen Printing

- Best for simple, bold patterns.

- Highly durable and cost-effective for large runs.

-

Digital Printing

- Allows photographic-quality images.

- Ideal for short runs and custom designs.

-

Sublimation Printing (for polyester Oxford)

- Dye becomes part of the fibers, making prints highly durable.

-

Heat Transfer Printing

- Prints are transferred from a special paper using heat.

6. How to Choose the Right Print Oxford Fabric

-

Material Composition –

- 100% cotton: Soft, breathable, natural feel.

- Polyester: Strong, water-resistant, and wrinkle-free.

- Blends: Best of both worlds.

-

Weave Density – Higher density means more durability but less breathability.

-

Printing Method – Select based on design complexity, quantity, and budget.

-

Coatings and Treatments – PU or PVC coatings for waterproofing; UV-resistant finishes for outdoor use.

-

Color Fastness – Ensure the fabric meets industry standards to prevent fading.

7. Maintenance Tips

- Washing – Use mild detergent; avoid bleach to preserve prints.

- Drying – Air-dry or tumble dry on low heat to prevent shrinkage.

- Ironing – Low to medium heat, preferably on the reverse side.

- Storage – Store in a cool, dry place to avoid mold growth.

8. Advantages Over Other Fabrics

- Compared to Canvas – Lighter, softer, and more breathable while still durable.

- Compared to Plain Oxford – Offers added visual interest through patterns and colors.

- Compared to Polyester Taffeta – More textured feel and better durability.

9. Environmental Considerations

Eco-friendly options are now available, including recycled polyester Oxford fabric and organic cotton Oxford fabric. Digital printing also reduces water and chemical waste compared to traditional methods.

10. Conclusion

Print Oxford fabric combines style, durability, and versatility, making it a favorite among designers, manufacturers, and consumers. With its wide range of patterns, printing techniques, and functional finishes, it can be adapted for everything from fashion apparel to heavy-duty outdoor gear.

English

English 简体中文

简体中文 русский

русский Español

Español