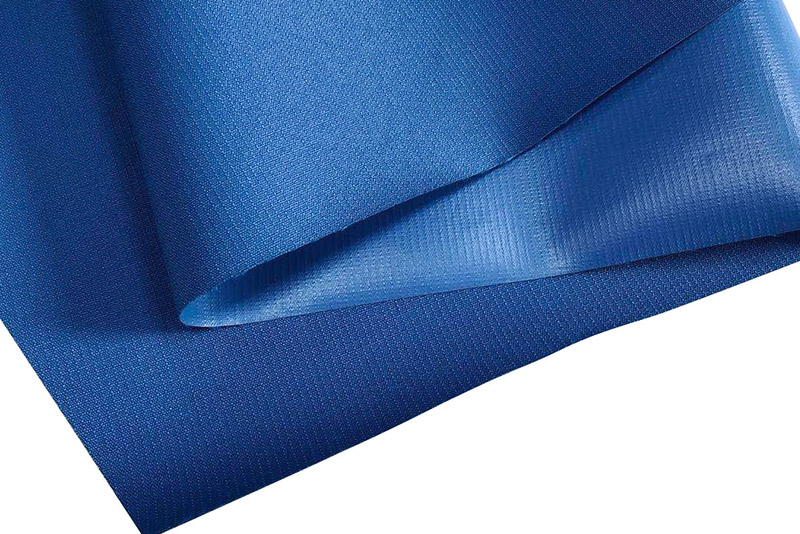

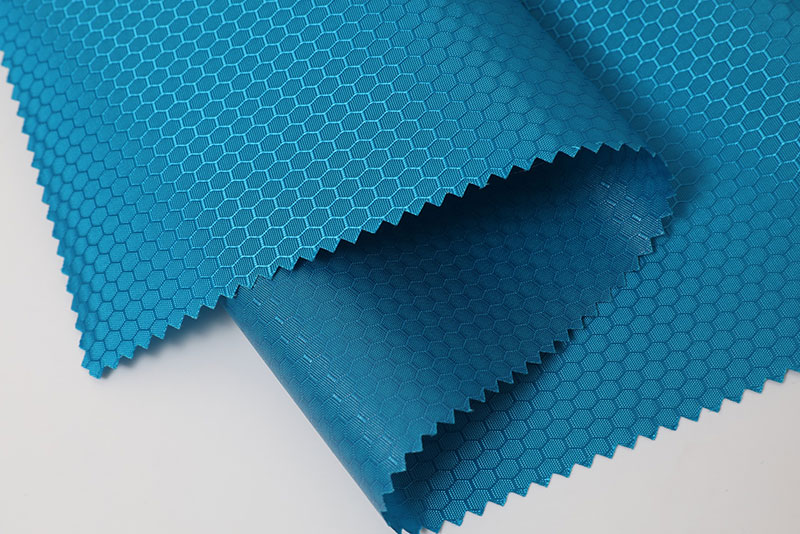

Print Oxford fabric is a woven textile that combines the classic Oxford weave structure with various surface printing techniques. Oxford fabric is traditionally characterized by its basket-like weave, created by using two thinner yarns woven against a thicker yarn. This structure provides a balance of durability, breathability, and a slightly textured surface. When enhanced with printed patterns, colors, or graphics, the fabric becomes both functional and visually appealing.

Printed Oxford fabric is widely used in bags, apparel, outdoor products, uniforms, and home textiles. Its popularity comes from its ability to maintain structural strength while offering flexible design options, making it suitable for both practical and decorative applications.

Basic Structure of Oxford Fabric

The foundation of print Oxford fabric lies in its unique weave structure. The Oxford weave uses paired warp yarns combined with single or paired weft yarns, creating a subtle checkerboard appearance. This construction enhances tear resistance and provides a soft yet firm hand feel.

Weave Density and Fabric Weight

Oxford fabrics are available in various densities and weights, typically ranging from lightweight versions for shirts and linings to heavy-duty grades for luggage and outdoor gear. The fabric weight directly influences printing clarity, durability, and end-use performance.

Materials Used in Print Oxford Fabric

Print Oxford fabric can be produced using different fiber materials, each contributing specific performance characteristics. Polyester Oxford is the most common, but nylon and blended options are also widely available.

- Polyester Oxford: High strength, wrinkle resistance, and colorfastness

- Nylon Oxford: Lightweight with superior abrasion resistance

- Poly-cotton Oxford: Improved breathability and softer touch

Printing Methods for Oxford Fabric

The printing process plays a crucial role in the appearance and performance of print Oxford fabric. Different printing methods are selected based on design complexity, production volume, and durability requirements.

Screen Printing

Screen printing is commonly used for bold patterns and solid color designs. It offers good color saturation and durability, making it suitable for bags, backpacks, and promotional products made from Oxford fabric.

Digital Printing

Digital printing allows for high-resolution images, gradients, and complex graphics. This method is ideal for customized or short-run production, providing flexibility in design without the need for extensive setup.

Heat Transfer Printing

Heat transfer printing applies pre-printed designs onto the fabric surface using heat and pressure. It is often used for logos, labels, or detailed artwork where precision is required.

Key Performance Characteristics

Print Oxford fabric is valued for its balanced performance properties, which make it adaptable to a wide range of environments and uses.

Durability and Tear Resistance

The Oxford weave structure provides excellent resistance to tearing and abrasion. This makes printed Oxford fabric suitable for products that undergo frequent handling or mechanical stress.

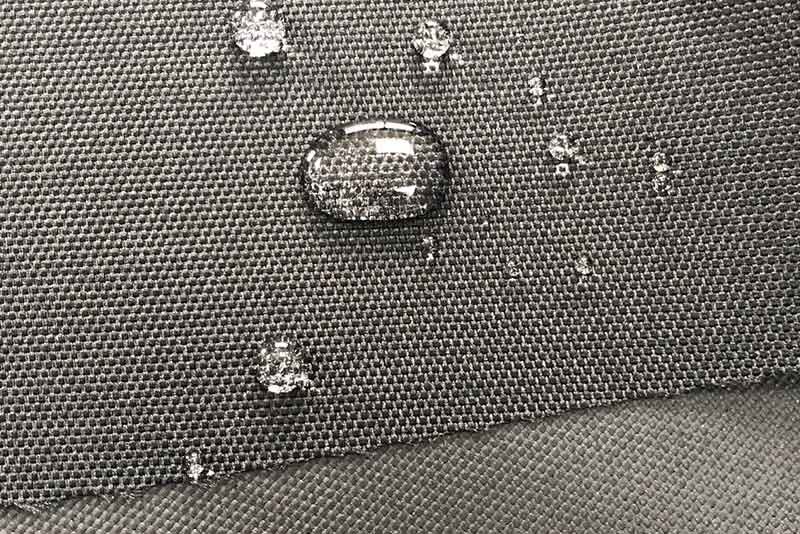

Color Fastness and Print Stability

High-quality print Oxford fabric demonstrates strong color fastness, ensuring that printed patterns remain vibrant even after repeated use or exposure to light and moisture.

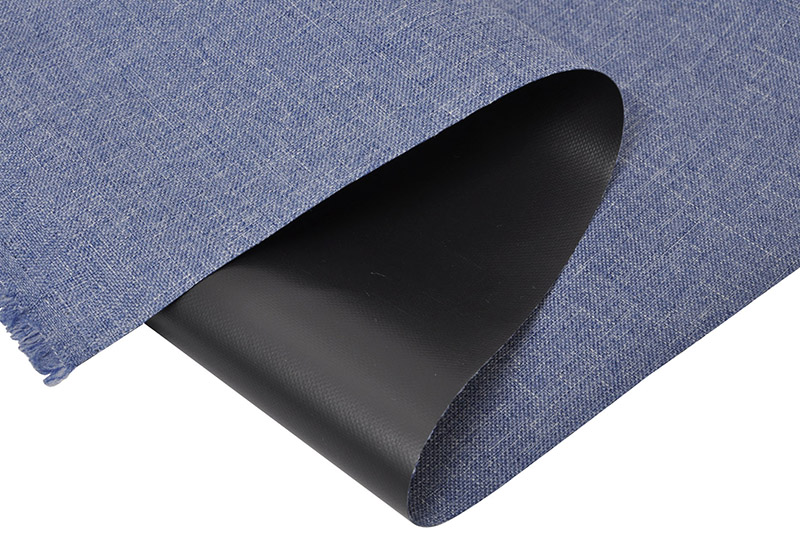

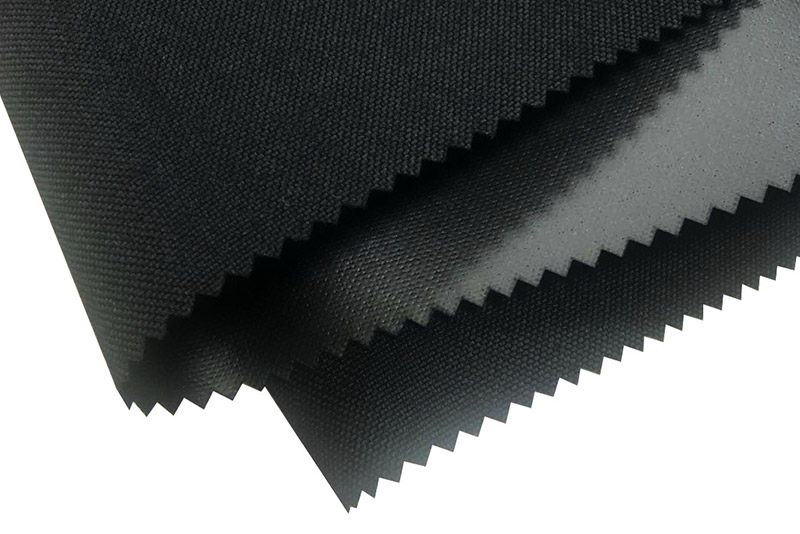

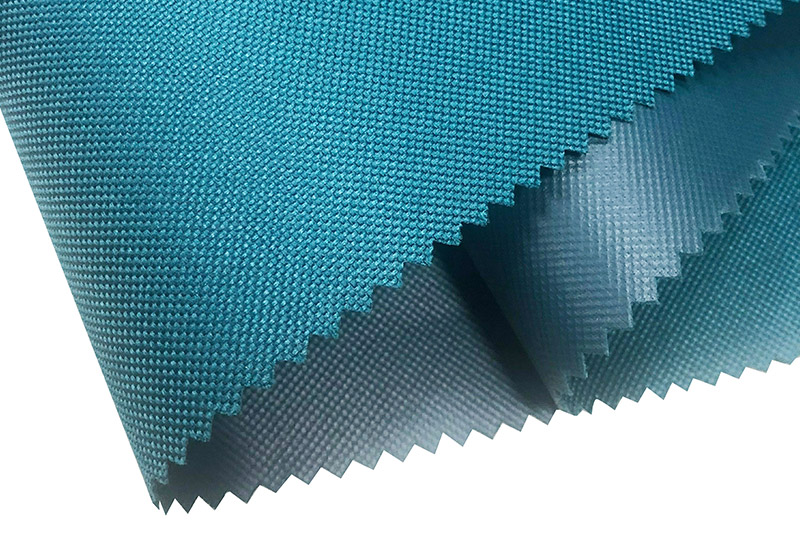

Water Resistance and Coating Options

Many print Oxford fabrics are treated with additional coatings to enhance water resistance and durability. Common coatings include polyurethane (PU) and polyvinyl chloride (PVC).

These coatings help protect printed designs while improving the fabric’s suitability for outdoor and utility products such as tents, rain covers, and travel bags.

Applications of Print Oxford Fabric

Print Oxford fabric is widely used across multiple industries due to its versatility and design flexibility.

- Backpacks, handbags, and luggage

- Outdoor equipment and camping gear

- Uniforms and workwear

- Home storage products and organizers

Print Oxford Fabric vs Other Printed Fabrics

Comparing print Oxford fabric with other printed textiles highlights its practical advantages in durability and structure.

| Feature | Print Oxford Fabric | Printed Canvas | Printed Plain Weave |

| Weave Structure | Basket-like Oxford weave | Plain heavy weave | Simple plain weave |

| Durability | High | Very high | Moderate |

| Weight | Medium | Heavy | Light to medium |

Care and Maintenance Considerations

Maintaining print Oxford fabric properly helps preserve both structural integrity and printed designs. Care instructions may vary depending on coatings and fiber content.

- Clean with mild detergent and low-temperature water

- Avoid harsh brushing on printed surfaces

- Air dry to maintain coating and print quality

Sustainability and Material Innovation

Sustainability has become an important consideration in print Oxford fabric production. Recycled polyester yarns and water-based printing inks are increasingly used to reduce environmental impact.

These innovations allow manufacturers to meet performance expectations while aligning with environmental and regulatory requirements.

How to Choose the Right Print Oxford Fabric

Choosing the appropriate print Oxford fabric involves evaluating factors such as fabric weight, printing method, coating type, and intended application. For outdoor products, coated polyester Oxford is often preferred, while uncoated or lightweight options suit apparel and accessories.

By aligning material specifications with functional needs, buyers can achieve the best balance between appearance, durability, and cost.

Conclusion: Why Print Oxford Fabric Is a Versatile Choice

Print Oxford fabric combines structural strength with design versatility, making it a reliable choice for a wide range of products. Its ability to support detailed printing while maintaining durability sets it apart from many other woven fabrics.

With ongoing advancements in printing and coating technologies, print Oxford fabric continues to expand its role in functional and decorative textile applications.

English

English 简体中文

简体中文 русский

русский Español

Español