Understanding Polyester Oxford Fabric and Its Yarn Types

Polyester Oxford fabric is widely known for its strength, durability, and versatility. It is used across industries such as luggage, outdoor gear, tents, and apparel. However, the performance of this fabric largely depends on the type of yarn used in weaving. The two most common types are DTY (Draw Textured Yarn) and FDY (Fully Drawn Yarn). While both are polyester-based, they differ significantly in production methods, texture, elasticity, and end applications. Understanding these differences helps manufacturers and designers choose the right material for their specific needs.

Production Process: DTY vs. FDY

The fundamental distinction between DTY and FDY lies in how the yarn is produced. Both begin as polyester chips that are melted and extruded through spinnerets, but the post-spinning processes differ greatly, resulting in unique characteristics.

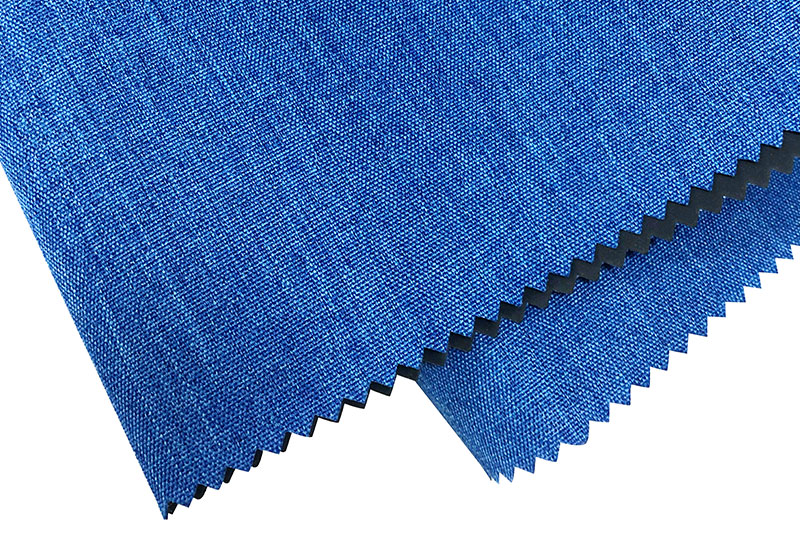

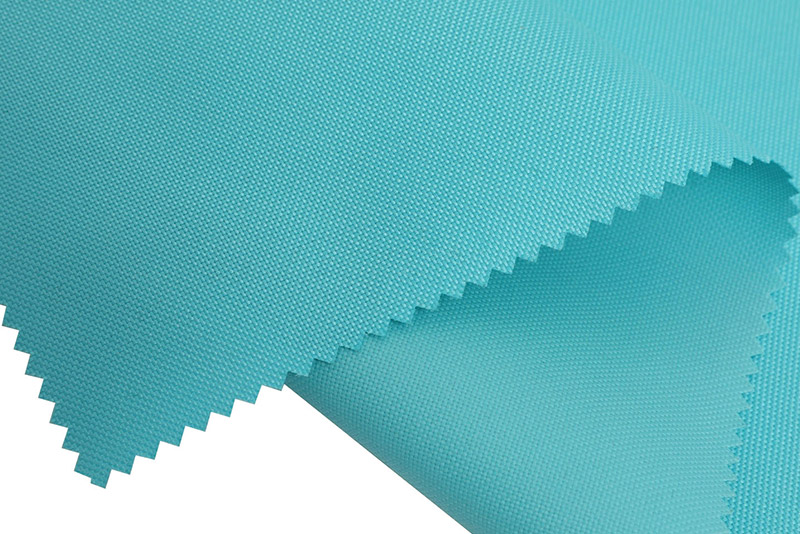

DTY (Draw Textured Yarn)

DTY is produced through a texturizing process in which partially oriented yarn (POY) is drawn and twisted using heat. This process introduces crimps, loops, and bulk into the yarn, making it more elastic and softer to the touch. DTY yarns are often used when comfort, flexibility, and visual texture are desired in the final fabric.

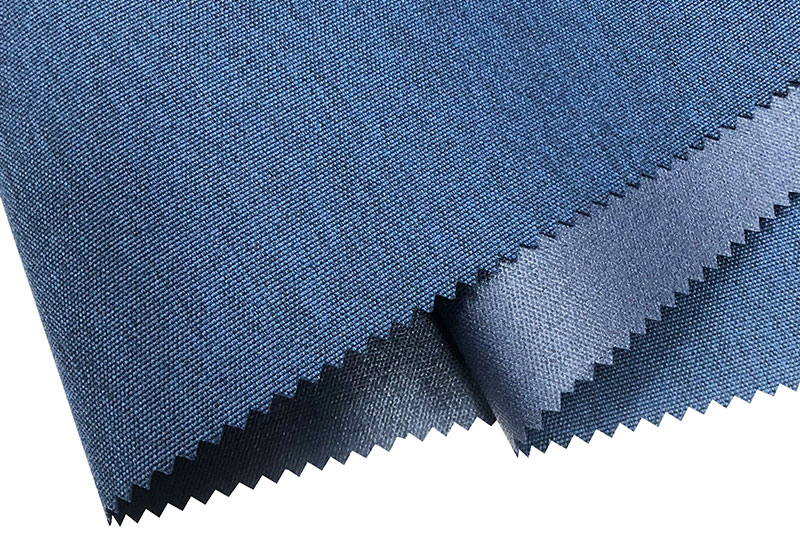

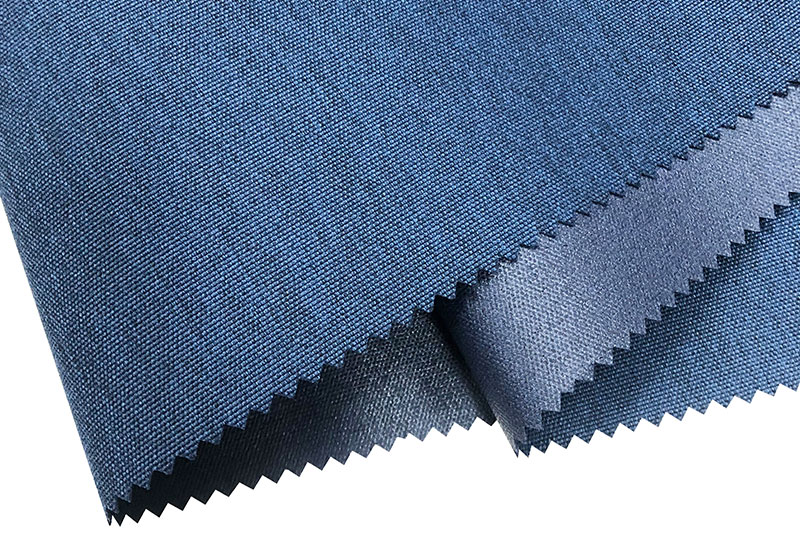

FDY (Fully Drawn Yarn)

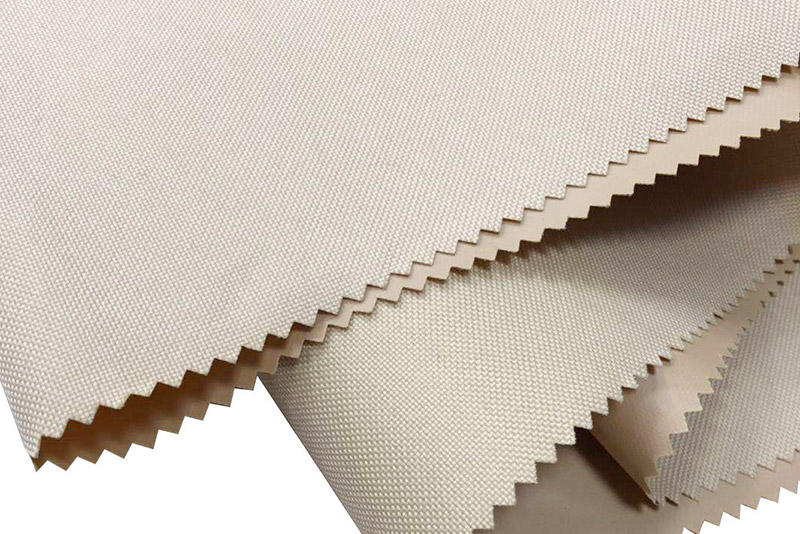

FDY is made by directly spinning and drawing the yarn at high speeds, achieving full orientation of the polymer molecules. This results in a smoother, stronger, and more lustrous yarn with minimal stretch. FDY is typically used when the fabric requires a sleek appearance and high dimensional stability, such as in luggage or upholstery fabrics.

Comparative Table: DTY vs. FDY Polyester Oxford Fabric

The table below summarizes the key technical and performance differences between DTY and FDY when used in polyester Oxford fabric production:

| Property | DTY Polyester Oxford Fabric | FDY Polyester Oxford Fabric |

| Yarn Structure | Crimped, textured, and elastic | Smooth, straight, and stable |

| Surface Appearance | Matte or semi-dull finish | Bright and glossy appearance |

| Softness | Soft and flexible | Firm and crisp |

| Tensile Strength | Moderate | High |

| Elasticity | Excellent | Low |

| Air Permeability | Better due to textured yarns | Lower because of tight structure |

| Best Applications | Garments, linings, casual bags, tents | Luggage, upholstery, outdoor covers |

| Cost | Generally lower | Higher due to processing precision |

Performance Differences in Practical Use

When selecting fabric for a product, understanding how DTY and FDY affect performance in real-world applications is essential. DTY fabrics offer comfort, flexibility, and aesthetic versatility, while FDY fabrics provide durability, structure, and strength. These differences determine which type is most suitable for specific end uses.

DTY for Comfort and Flexibility

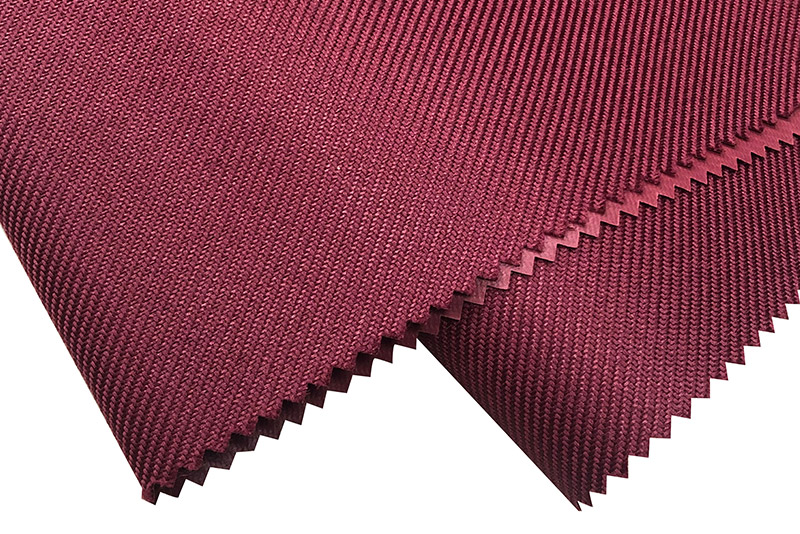

DTY Polyester Oxford Fabric is commonly chosen for items requiring softness and flexibility, such as jackets, lightweight tents, and fashion accessories. Its textured surface allows for better air circulation and breathability. The natural elasticity of DTY helps prevent wrinkling and enhances comfort, making it suitable for products that experience frequent handling or folding.

FDY for Strength and Structure

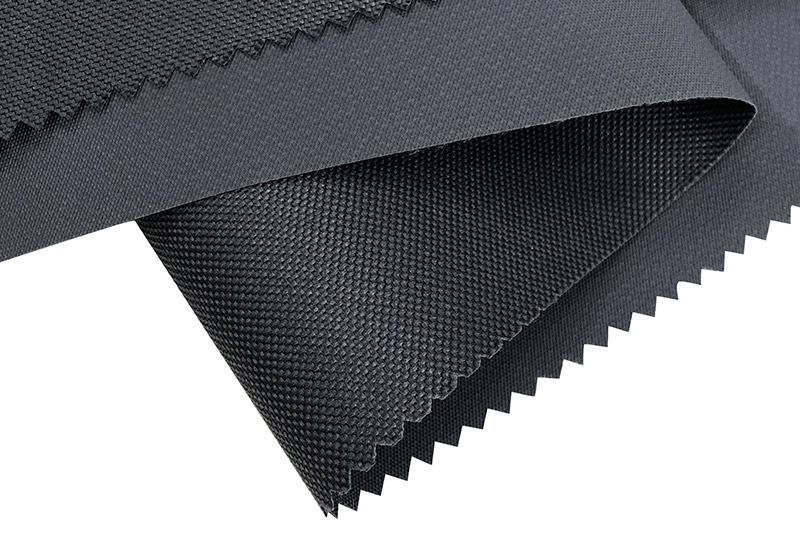

FDY Polyester Oxford Fabric, on the other hand, is used for heavy-duty applications such as backpacks, travel bags, and protective covers. Its tightly woven structure provides high tensile strength and resistance to abrasion, ensuring the material retains shape under stress. The glossy appearance also gives FDY fabric a professional, clean look that is preferred in industrial and outdoor products.

Durability and Maintenance Comparison

Both DTY and FDY Polyester Oxford fabrics are known for their durability, but the type of yarn influences how they perform over time and under different environmental conditions.

- DTY fabrics may show slight pilling or surface wear over extended use, especially under heavy friction.

- FDY fabrics are more resistant to tearing and abrasion, ideal for long-term outdoor or travel applications.

- Both types resist moisture, mildew, and UV exposure, but FDY’s denser weave offers slightly better water repellency.

- DTY fabrics are easier to wash and dry due to their lighter, airier texture.

Applications Across Industries

The choice between DTY and FDY Polyester Oxford Fabric depends heavily on the product’s intended use. Each has distinct advantages suited for specific industries and functions.

Common Uses for DTY Polyester Oxford Fabric

- Fashion accessories such as handbags, purses, and caps

- Outdoor products like lightweight tents and seat covers

- Casual bags and backpacks requiring a soft texture

- Garment linings and apparel with breathable structure

Common Uses for FDY Polyester Oxford Fabric

- Heavy-duty backpacks and travel luggage

- Upholstery and automotive interiors

- Outdoor furniture and industrial covers

- Protective tarpaulins and awnings

Choosing Between DTY and FDY: Practical Considerations

When choosing between DTY and FDY Polyester Oxford fabrics, manufacturers should consider both the aesthetic and functional requirements of the final product. DTY’s elasticity and comfort make it perfect for flexible and fashionable applications, while FDY’s rigidity and shine provide structure and strength for more demanding uses.

Key Decision Factors

- If softness and breathability are priorities, DTY is the better choice.

- For structural integrity and long-term durability, FDY is recommended.

- Budget considerations also matter—DTY fabrics are often more cost-effective.

- Environmental exposure: FDY performs better under continuous sunlight or moisture.

Conclusion

The difference between DTY and FDY Polyester Oxford Fabric extends far beyond appearance—it influences performance, comfort, durability, and application. DTY fabrics offer elasticity, breathability, and a matte aesthetic, ideal for apparel and lightweight gear. FDY fabrics, with their strength, gloss, and rigidity, serve better in heavy-duty or outdoor uses. By understanding these distinctions, manufacturers and designers can make informed choices that balance functionality, cost, and consumer appeal, ensuring optimal results for every product category.

English

English 简体中文

简体中文 русский

русский Español

Español