In modern manufacturing and the outdoor products industry, the performance of the material directly determines the service life and quality of the product. Oxford PVC Coated Fabric, as a fabric that combines durability, waterproofness and versatility, has been popular in many fields in recent years and has become an ideal material for products such as tents, backpacks, waterproof tarpaulins, raincoats, etc.

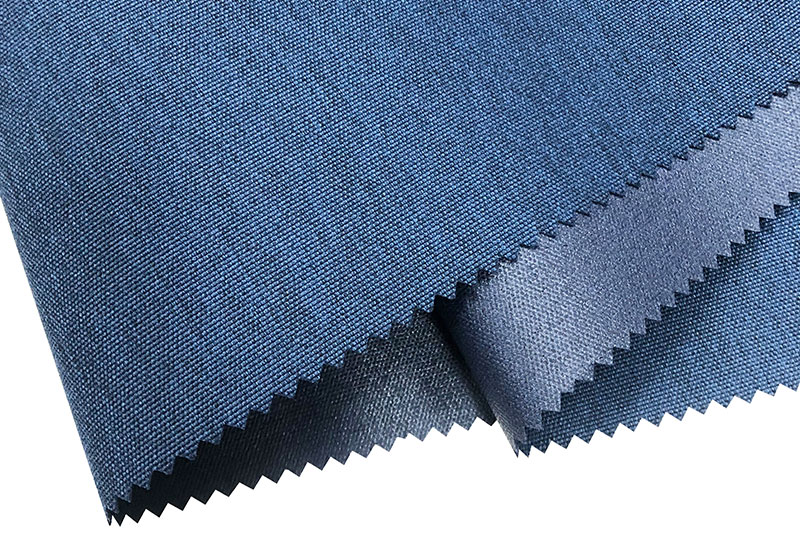

Oxford cloth was originally a polyester or nylon fabric made of plain or twill weave, named after it was first popular at Oxford University in the UK. "PVC coating" refers to a layer of polyvinyl chloride (PVC) coated on the surface of Oxford cloth, making it more waterproof, oil-proof, and corrosion-resistant.

This fabric combines the strength of Oxford cloth with the protective layer of PVC, maintaining softness and processability while greatly enhancing its weather resistance and tear resistance.

Material structure and characteristics

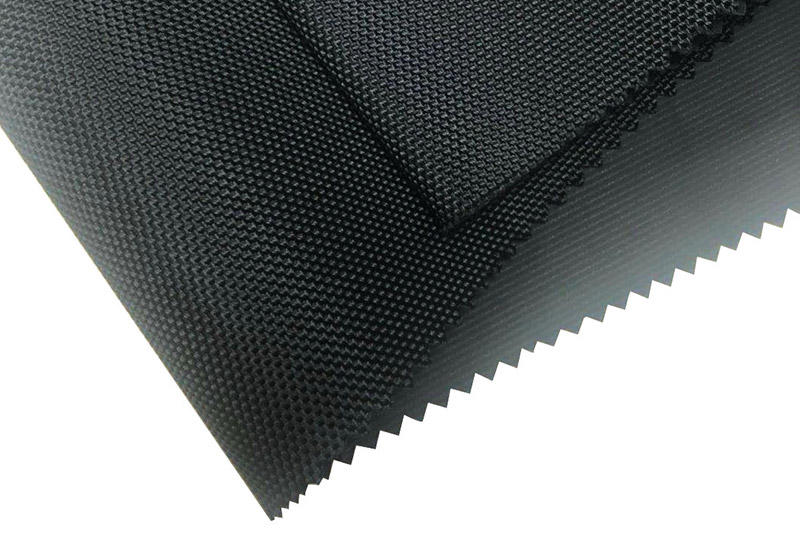

The core of Oxford PVC coated cloth consists of three parts:

Base fabric layer: mostly polyester or nylon yarns of different densities such as 300D, 600D, 900D;

Adhesive layer: firmly bond PVC to base fabric;

Coating layer: high molecular PVC material, evenly coated by hot pressing process to form a waterproof and anti-aging surface layer.

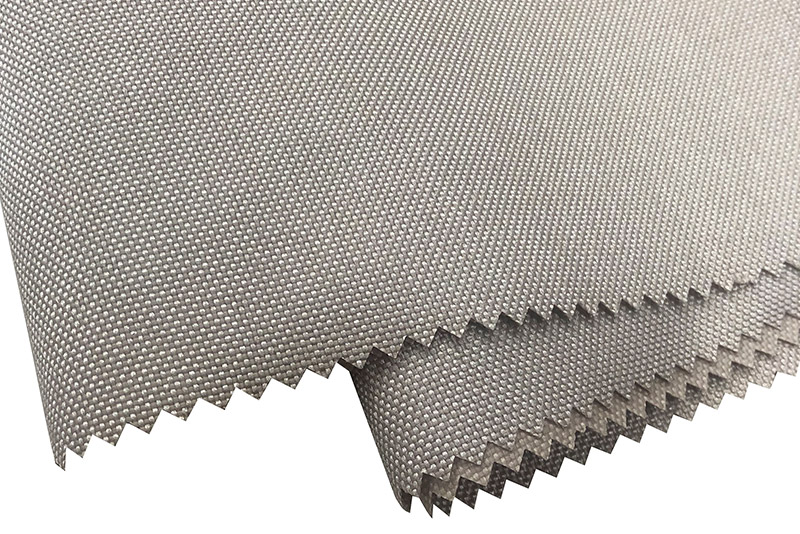

This structure gives the material the following significant advantages:

Excellent waterproof performance: The PVC layer forms a solid waterproof barrier that can withstand rain and moisture penetration;

Excellent tear resistance and abrasion resistance: suitable for frequent folding and friction applications;

Flame retardant and anti-ultraviolet function (optional): meet high safety requirements such as outdoor and industrial;

Easy to clean and process: PVC surface is smooth, not easy to adhere to dirt, and easy to heat press or high-frequency welding.

Wide range of applications

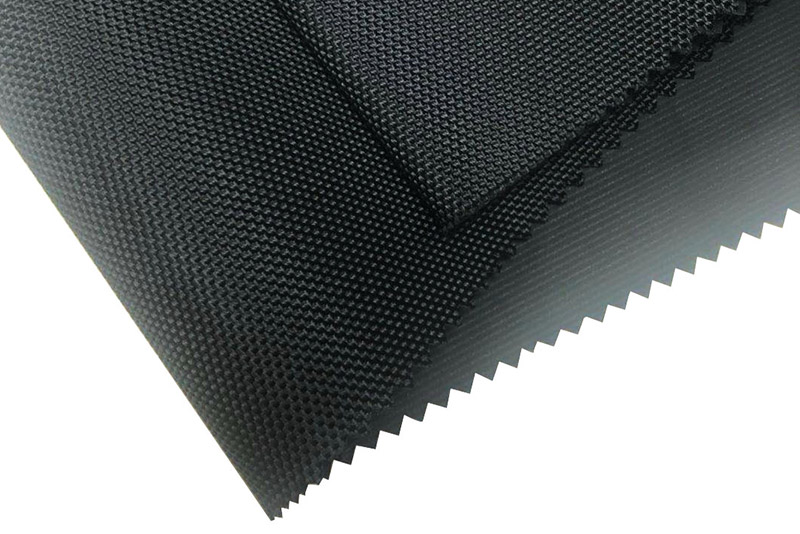

The application of Oxford PVC Coated Fabric covers multiple industries:

Outdoor products: such as tents, backpacks, folding chairs, outdoor awnings, etc., durable and waterproof;

Transportation and logistics: used for truck canvas, container covers, luggage bags, etc., with high tensile strength;

Industrial use: used for protective covers, waterproof curtains, mechanical shielding cloth;

Daily necessities: such as umbrellas, raincoats, shopping bags, etc., waterproof and durable, with various styles;

Agricultural facilities: used for greenhouse shed cloth, agricultural cover cloth, etc., effectively waterproof and UV-proof.

Environmental protection and development trends

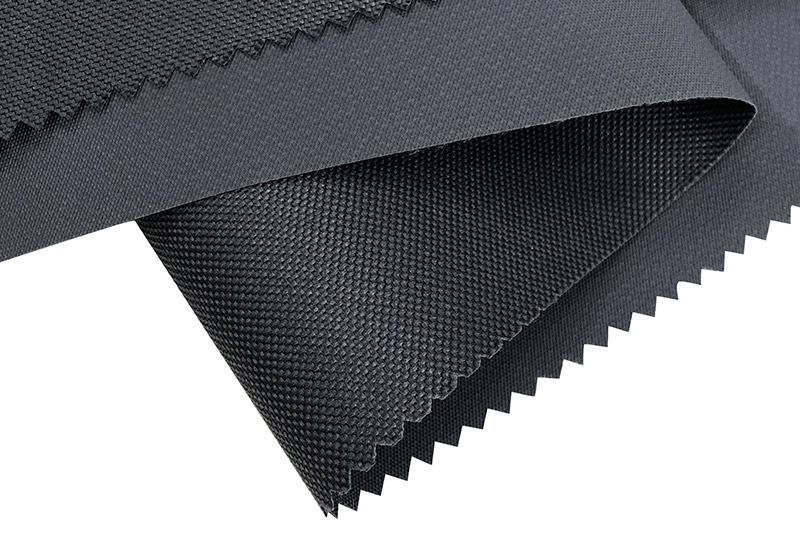

With the improvement of global environmental awareness, the environmental pressure faced by traditional PVC materials is gradually increasing. Therefore, more and more manufacturers are developing renewable PVC or low-toxic and environmentally friendly coating materials to reduce the impact on the environment. At the same time, some manufacturers have introduced alternative materials such as **thermoplastic polyurethane (TPU)** for some high-end needs.

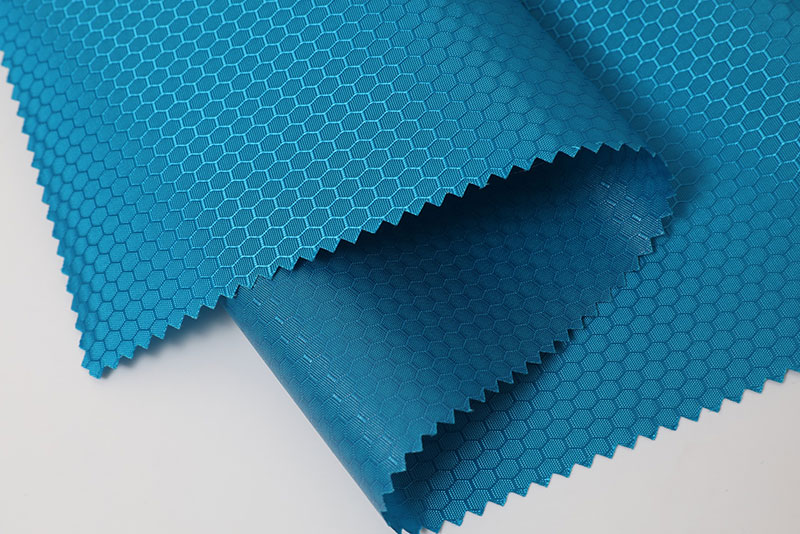

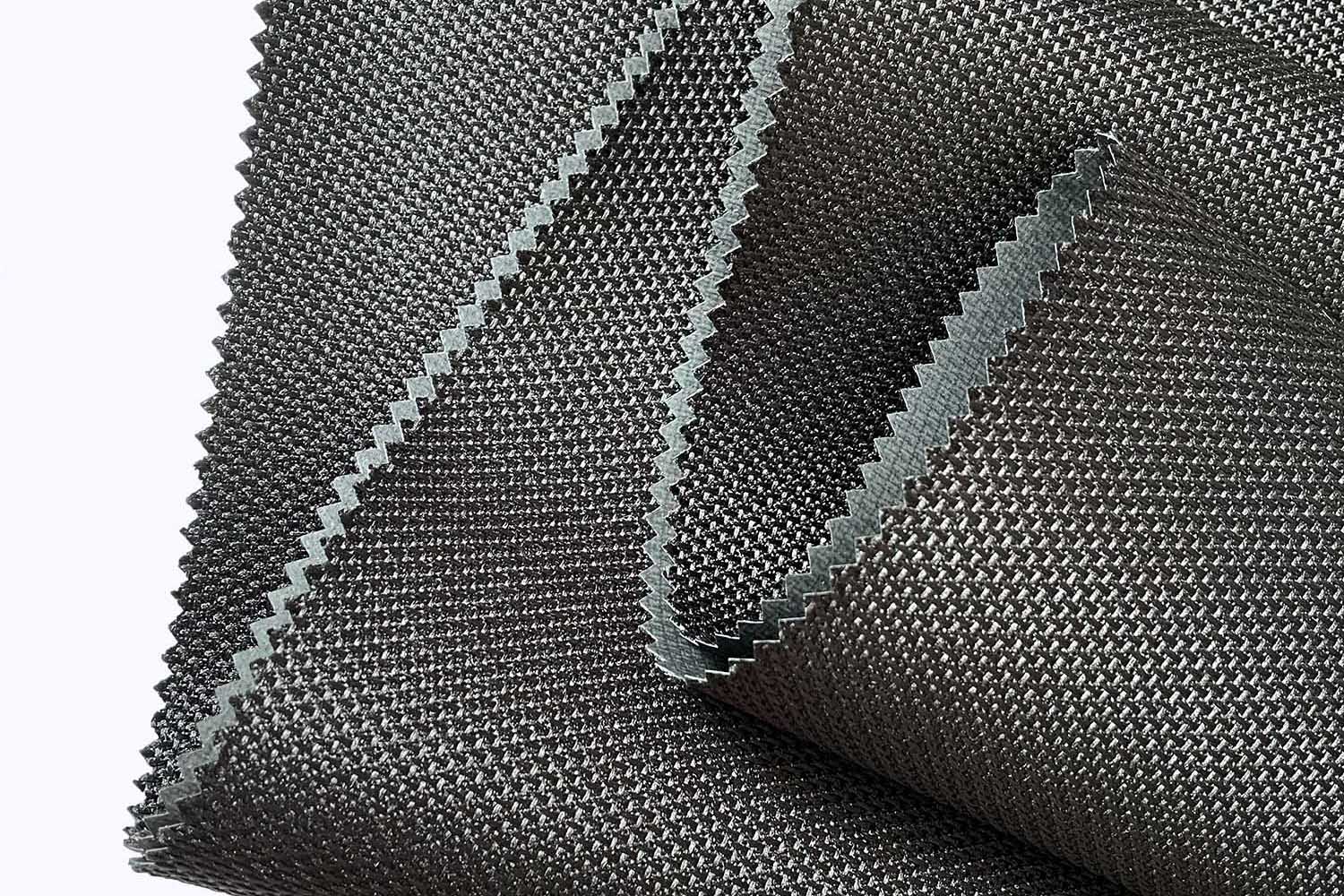

Technically, Oxford PVC coated fabrics are moving towards lighter weight, higher strength, and richer patterning. Through digital printing, composite multifunctional film layers and other methods, the material not only continues to improve in performance, but also becomes more beautiful and fashionable, in line with modern consumer trends.

Oxford PVC Coated Fabric has become the preferred material for many industries due to its excellent waterproof, wear-resistant and strong plasticity. With the advancement of technology and the integration of environmental protection concepts, this material will continue to innovate in the future and show its unlimited potential in more application scenarios. Whether it is outdoor adventure or industrial protection, it is a high-quality choice that can truly stand the test of time and the environment.

English

English 简体中文

简体中文 русский

русский Español

Español