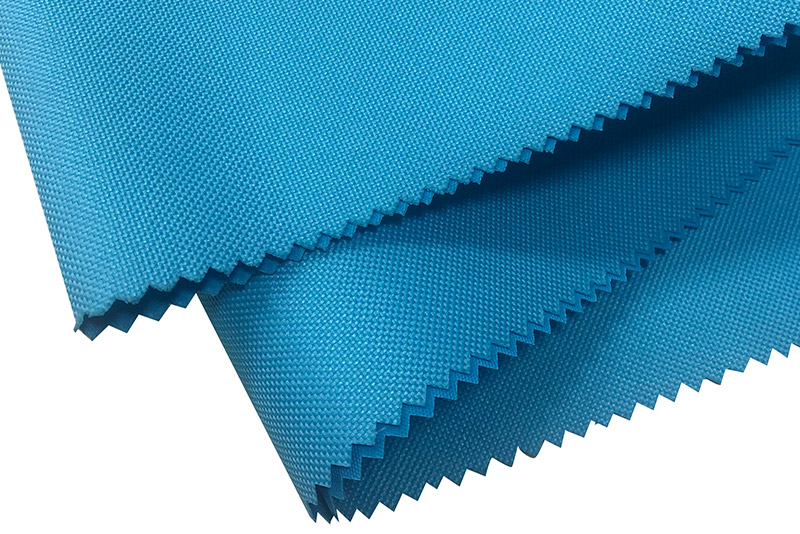

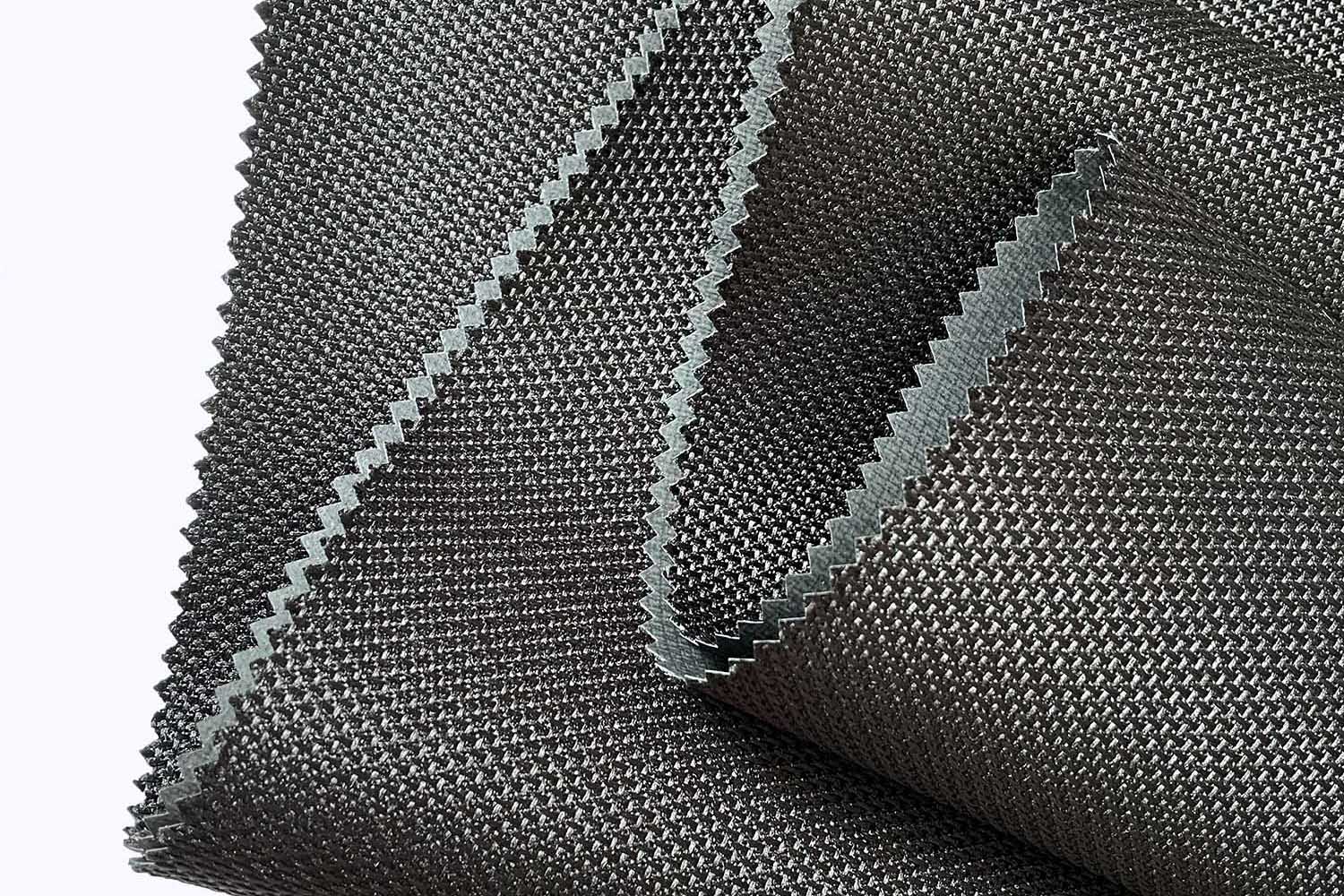

600d ripstop oxford fabric is a type of woven material known for its excellent durability, tear resistance, and water-repellent properties. The "600d" refers to the density of the fabric threads, indicating a high tensile strength ideal for heavy-duty applications. Its ripstop pattern, created by reinforcing threads woven at regular intervals, prevents small tears from spreading, enhancing the material's lifespan.

Material Composition and Structure

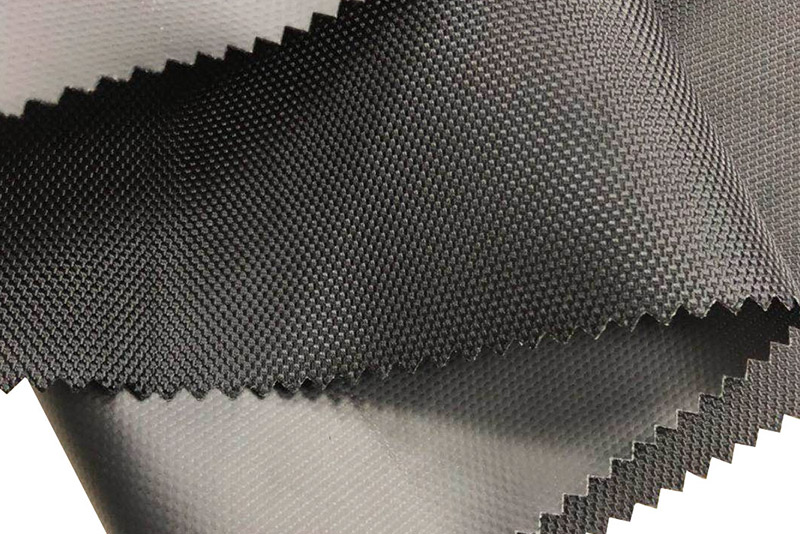

Typically, 600d ripstop oxford fabric is made from polyester or nylon fibers. Polyester provides excellent UV resistance and dimensional stability, while nylon offers superior elasticity and abrasion resistance. The ripstop weaving technique integrates thicker threads at intervals to form a grid, making the fabric less prone to tearing and stretching under stress.

Thread Count and Denier

The "600d" denotes the denier, measuring the weight of 9,000 meters of thread in grams. A higher denier indicates thicker and more durable threads. The thread count in ripstop oxford fabrics can vary, with common weaves providing a balance between strength and flexibility suitable for bags, tents, and outdoor equipment.

Physical Properties

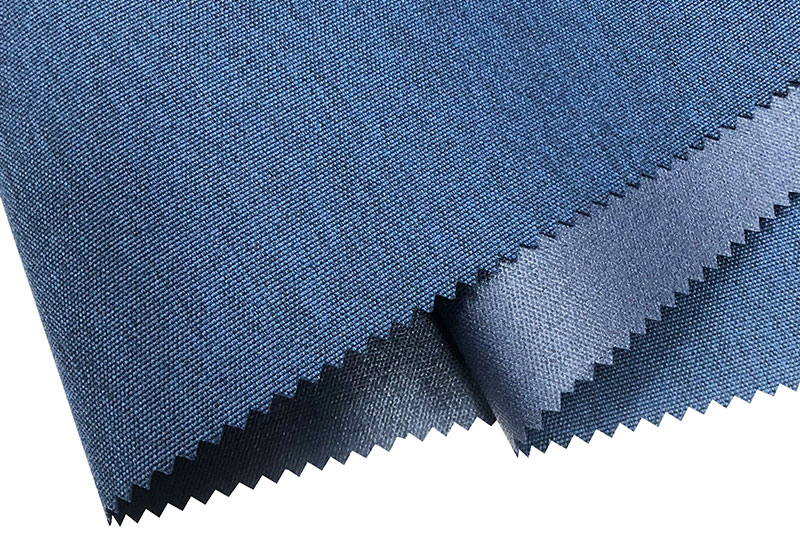

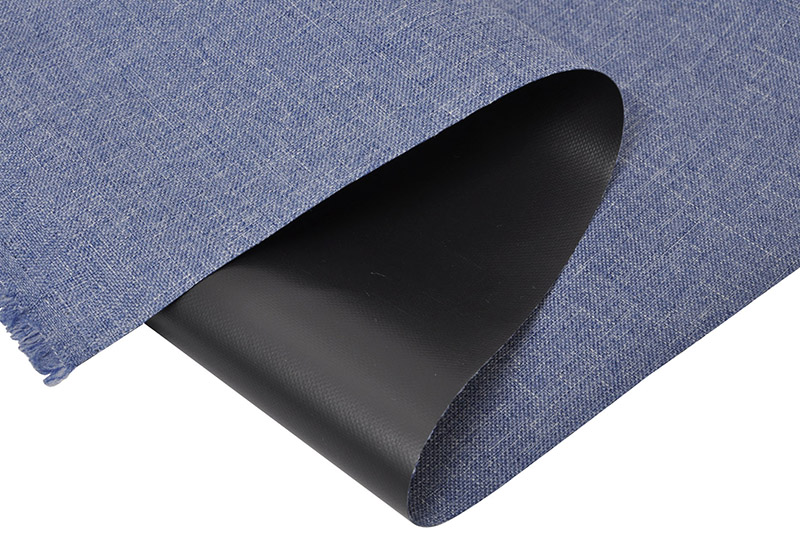

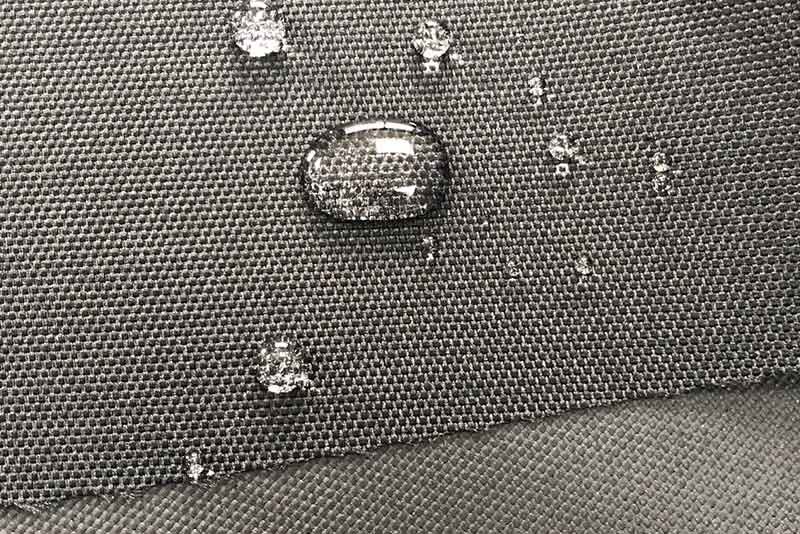

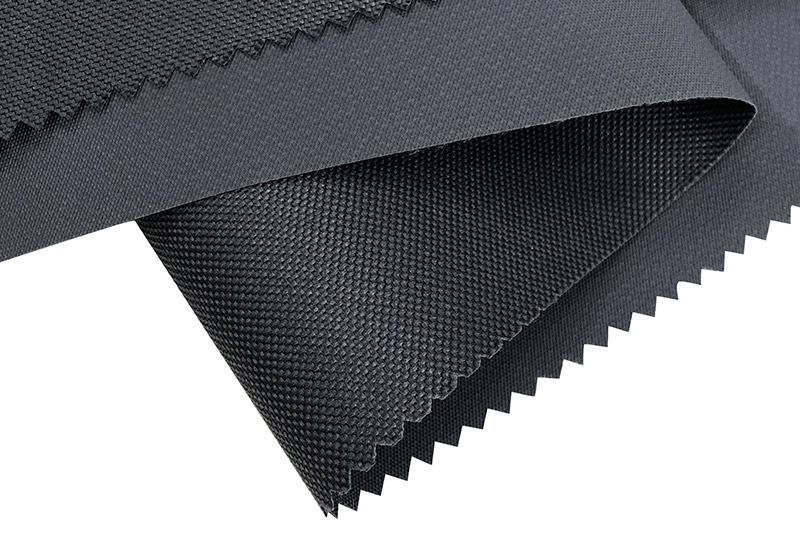

600d ripstop oxford fabric is lightweight yet strong, offering high tensile strength and abrasion resistance. Its tear-resistant grid pattern ensures durability under heavy use. The fabric can be coated with polyurethane (PU) or polyvinyl chloride (PVC) to enhance water resistance, making it ideal for rain gear and protective covers.

Water Resistance

A PU or PVC coating adds a waterproof layer, preventing liquid penetration while maintaining breathability. This feature is essential for outdoor backpacks, tents, and tarpaulins, where exposure to moisture is common.

Abrasion and Tear Resistance

The combination of high-denier fibers and ripstop weaving provides exceptional resistance against abrasions, cuts, and tearing. This makes the fabric suitable for applications requiring frequent handling or contact with rough surfaces.

Common Applications

600d ripstop oxford fabric is widely used in industries requiring durable, weather-resistant textiles. Its applications include:

- Outdoor backpacks, duffle bags, and luggage

- Tents, tarpaulins, and camping gear

- Protective covers for vehicles, machinery, and furniture

- Sports equipment and safety gear

- Industrial packaging and storage solutions

Backpacks and Travel Gear

The durability, tear resistance, and water-repellent properties make 600d ripstop oxford fabric ideal for backpacks, luggage, and travel accessories. Reinforced stitching and ripstop structure ensure long-term reliability even under heavy loads.

Outdoor and Camping Equipment

Tents, tarpaulins, and awnings benefit from this fabric's high abrasion and water resistance. The lightweight design combined with strength allows for easy transportation without compromising durability.

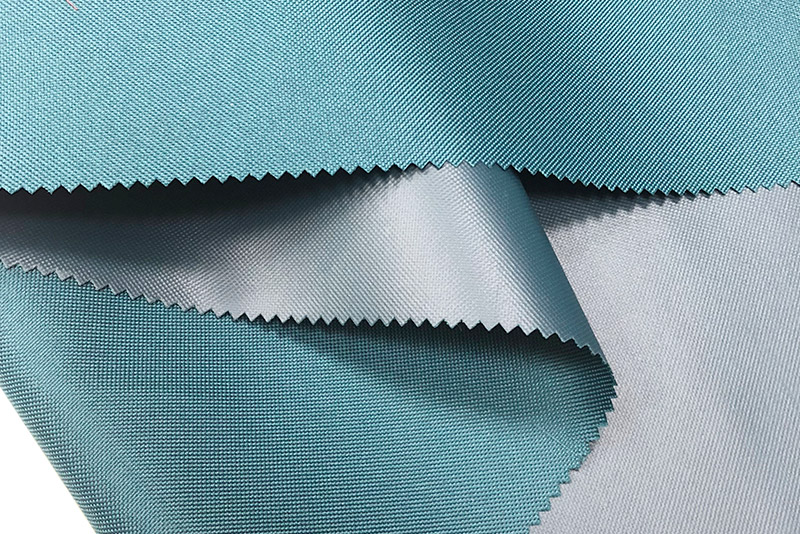

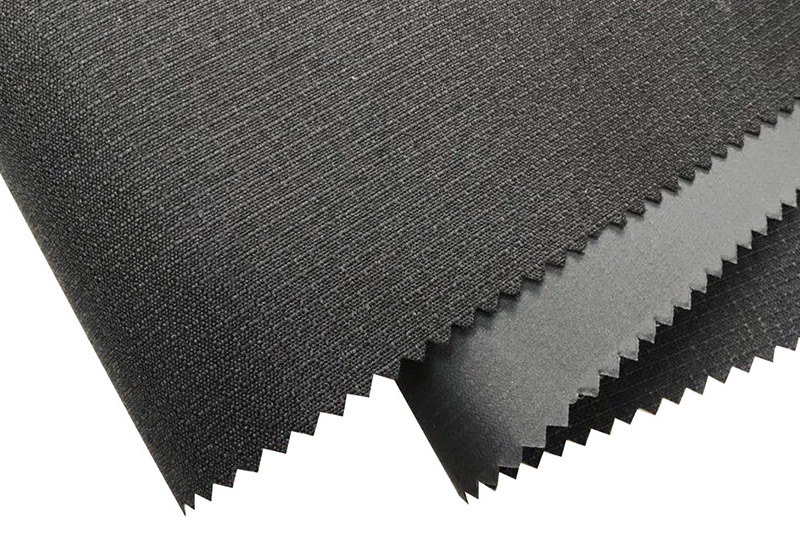

Manufacturing and Finishing Techniques

The production of 600d ripstop oxford fabric involves weaving high-denier threads with interspersed reinforcing threads. The fabric can undergo additional finishing processes, such as PU or PVC coating, laminating, and anti-fading treatments. These treatments enhance water resistance, UV protection, and color retention for outdoor and industrial applications.

Coating Methods

PU coating involves applying a polyurethane layer to the fabric, creating a flexible waterproof barrier. PVC coating adds rigidity and superior waterproofing but may slightly reduce flexibility. Both coatings can be adjusted to achieve desired properties for specific applications.

Printing and Aesthetics

600d ripstop oxford fabric can be dyed or printed with various patterns and colors, enhancing aesthetic appeal for consumer products like backpacks, luggage, and apparel. Modern digital printing ensures vibrant, fade-resistant designs without compromising fabric strength.

Care and Maintenance

Maintaining 600d ripstop oxford fabric is straightforward due to its durable and water-repellent nature. Regular cleaning with mild soap and water prevents dirt accumulation. Avoid harsh chemicals or abrasive brushes that may damage the coating or fabric surface. For coated fabrics, reapplication of waterproofing sprays can extend the protective properties.

Storage Recommendations

Store dry and away from direct sunlight to prevent UV-induced degradation. Proper folding or rolling avoids creases that can weaken the ripstop grid over time.

Advantages and Limitations

The key advantages of 600d ripstop oxford fabric include high durability, tear resistance, water repellency, and lightweight construction. Its versatility makes it suitable for a wide range of consumer, outdoor, and industrial applications. However, the fabric may have limitations in extreme conditions, such as prolonged UV exposure or extremely heavy mechanical loads, which can gradually degrade coatings or fibers.

Pros

- High tensile and tear resistance

- Water-repellent and weather-resistant

- Lightweight and flexible

- Durable for heavy-duty applications

- Customizable with coatings, colors, and prints

Cons

- Coatings can wear over time

- Limited UV resistance without special treatment

- May be less breathable if heavily coated

Conclusion

600d ripstop oxford fabric is a high-performance material ideal for applications requiring durability, tear resistance, and water repellency. Its versatility and strength make it suitable for backpacks, tents, protective covers, and industrial solutions. Understanding its properties, finishing techniques, and care requirements ensures optimal use and long-term reliability.

English

English 简体中文

简体中文 русский

русский Español

Español