Nylon has revolutionized the textile industry since its introduction in the 1930s, becoming one of the most versatile and widely used synthetic fabrics in clothing production. This remarkable material offers exceptional strength, elasticity, and durability while remaining lightweight and comfortable. Understanding the different types of nylon fabric and their specific applications can help designers, manufacturers, and consumers make informed decisions about garment selection and production. This comprehensive guide explores the various nylon fabric types, their distinctive characteristics, and how they're utilized in creating modern clothing.

What Makes Nylon Fabric Unique

Nylon is a synthetic polymer created through a chemical process called polymerization, where petroleum-based materials are transformed into long molecular chains. This engineered structure gives nylon its distinctive properties that natural fibers cannot replicate. The fabric demonstrates remarkable resistance to abrasion, making it ideal for garments subjected to frequent wear and friction. Its quick-drying capabilities and moisture-wicking properties keep wearers comfortable during physical activities, while its inherent elasticity allows garments to retain their shape even after repeated stretching.

Unlike natural fibers, nylon resists mildew, moths, and fungal growth, extending garment lifespan significantly. The fabric also accepts dyes readily, producing vibrant, long-lasting colors that resist fading. These combined characteristics have made nylon indispensable in modern clothing manufacturing, particularly for activewear, outerwear, and performance garments where durability and functionality are paramount.

Types of Nylon Fabric

Nylon 6

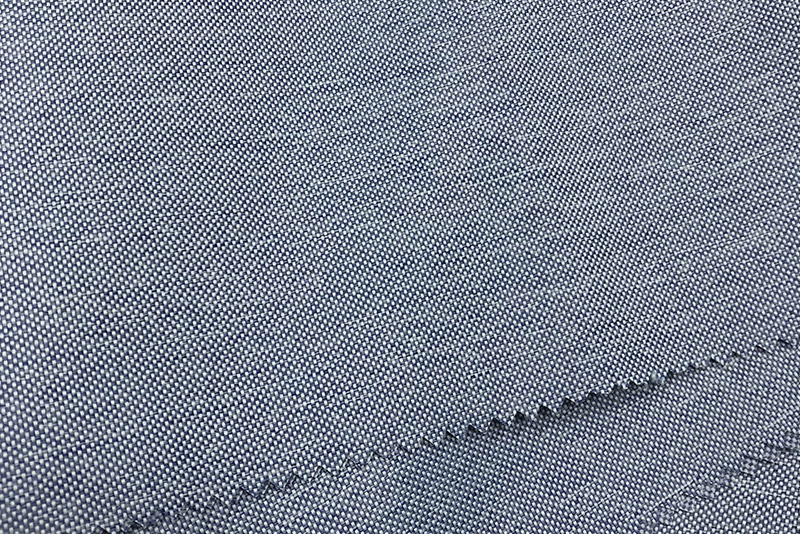

Nylon 6, also known as polycaprolactam, represents one of the most common nylon types in clothing production. Created through ring-opening polymerization of caprolactam, this fabric offers excellent elasticity and resilience. Nylon 6 exhibits superior dyeability compared to other nylon variants, allowing manufacturers to achieve rich, consistent colors across fabric batches. The material demonstrates good resistance to chemicals and abrasion while maintaining a soft, comfortable hand feel that works well for garments worn directly against skin.

This type of nylon is particularly popular in hosiery, lingerie, and activewear where stretch, recovery, and comfort are essential. Its ability to blend seamlessly with other fibers like spandex or cotton creates versatile fabric combinations that enhance both performance and aesthetic appeal.

Nylon 6,6

Nylon 6,6, scientifically known as polyhexamethylene adipamide, is synthesized from hexamethylene diamine and adipic acid. This variant offers higher tensile strength and better heat resistance than Nylon 6, making it ideal for applications requiring enhanced durability. The fabric maintains its structural integrity at higher temperatures, which proves valuable in garments that undergo frequent heat exposure during wear or laundering.

The superior strength characteristics of Nylon 6,6 make it the preferred choice for outdoor clothing, heavy-duty workwear, and tactical garments where fabric failure is not acceptable. Its slightly stiffer hand compared to Nylon 6 doesn't diminish its popularity in applications where durability outweighs softness concerns.

Ripstop Nylon

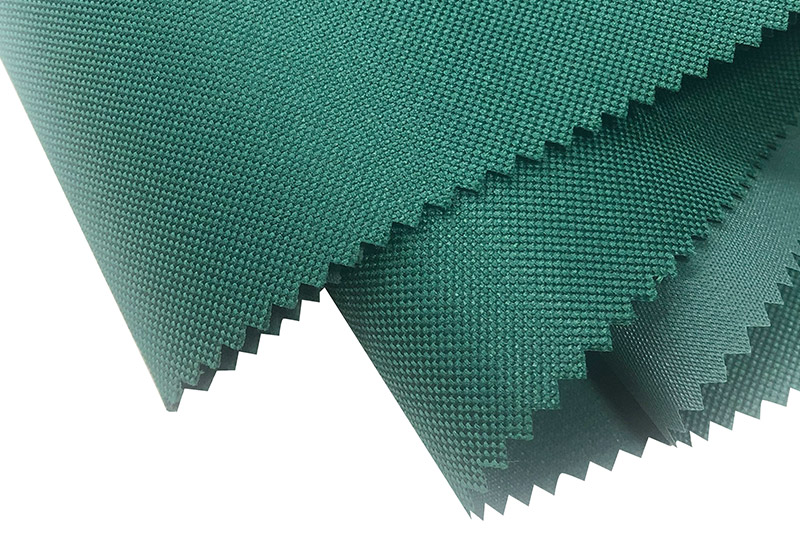

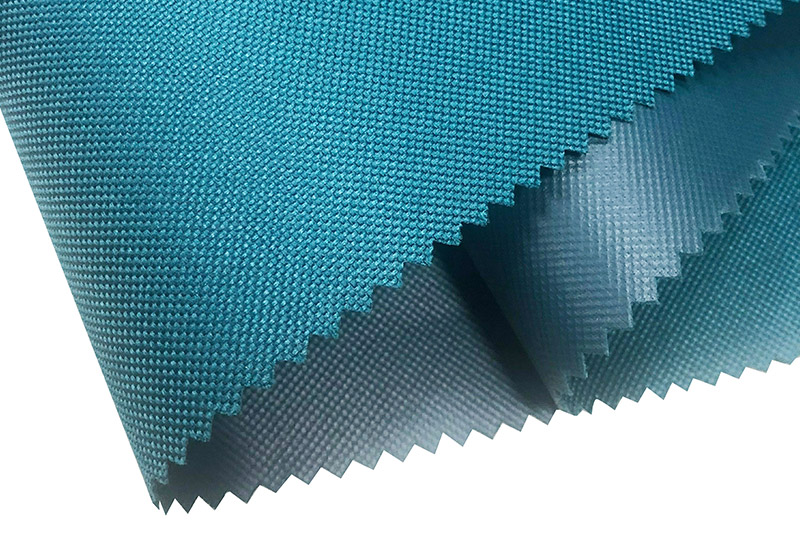

Ripstop nylon features a specialized weaving technique where reinforcement threads are interwoven at regular intervals, creating a distinctive crosshatch or grid pattern. This construction prevents tears from spreading across the fabric, as the reinforcement threads stop rips at the grid intersections. The resulting material is exceptionally lightweight yet remarkably tear-resistant, making it invaluable for applications where weight reduction is crucial but durability cannot be compromised.

Ripstop nylon's unique structure makes it perfect for windbreakers, rain jackets, outdoor gear, and parachute-style clothing. The fabric can be coated with water-resistant or waterproof treatments without adding significant weight, further enhancing its utility in performance outerwear.

Ballistic Nylon

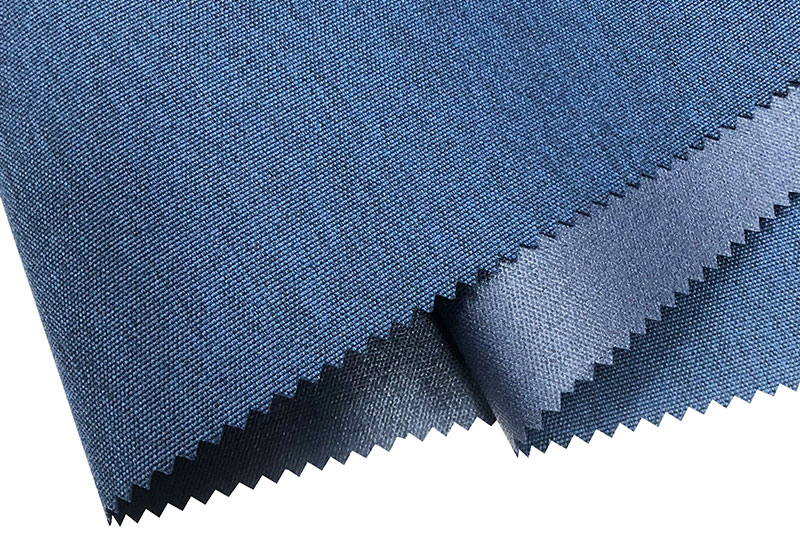

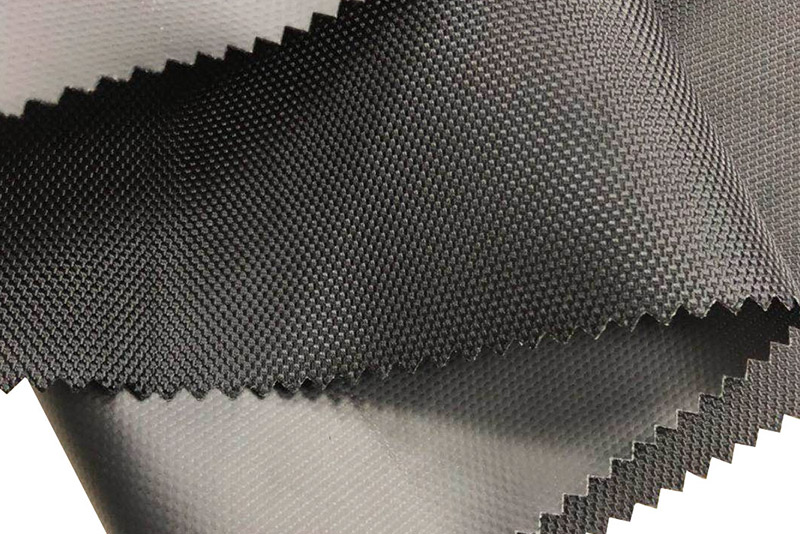

Originally developed for military flak jackets during World War II, ballistic nylon represents the heavyweight champion of nylon fabrics. This thick, extremely durable material is woven from highly twisted nylon fibers in a basket-weave pattern, creating a fabric with exceptional resistance to abrasion, punctures, and tears. While too heavy and stiff for most clothing applications, ballistic nylon finds its place in specific garment components and accessories.

The fabric commonly reinforces high-stress areas in workwear, protective clothing, and tactical garments. Knee patches, elbow reinforcements, and pocket reinforcements in work pants and jackets frequently utilize ballistic nylon to extend garment life in areas prone to wear and tear.

Taslan Nylon

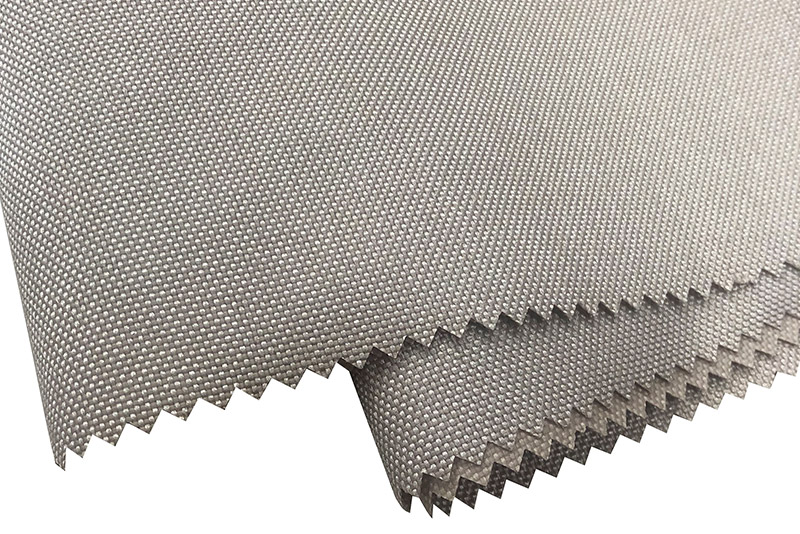

Taslan nylon undergoes a specialized air-texturing process that creates a fabric with a soft, natural hand feel resembling cotton. This treatment breaks up the smooth nylon filaments, introducing texture and reducing the synthetic appearance typical of standard nylon fabrics. The resulting material maintains nylon's performance benefits while offering improved comfort and a more natural aesthetic that appeals to consumers seeking technical performance without the synthetic look.

This fabric type works exceptionally well in casual outdoor wear, lightweight jackets, and sportswear where the combination of technical performance and natural appearance creates market appeal. The textured surface also provides better grip and less slipperiness than smooth nylon variants.

Nylon Fabric Applications in Clothing

Activewear and Sportswear

Nylon dominates the activewear market due to its exceptional moisture management, durability, and stretch properties. The fabric efficiently wicks perspiration away from skin, transporting it to the fabric surface where it evaporates quickly, keeping athletes dry and comfortable during intense physical activity. This moisture management prevents the heavy, clingy feeling associated with sweat-soaked garments, maintaining comfort throughout workouts.

- Yoga pants and leggings utilizing nylon-spandex blends for four-way stretch

- Running shorts and tights with moisture-wicking properties

- Sports bras requiring support and quick-dry capabilities

- Athletic tops and tank tops for training and competition

- Compression garments for improved circulation and muscle support

- Swimwear that resists chlorine degradation and maintains shape

Outerwear and Weather Protection

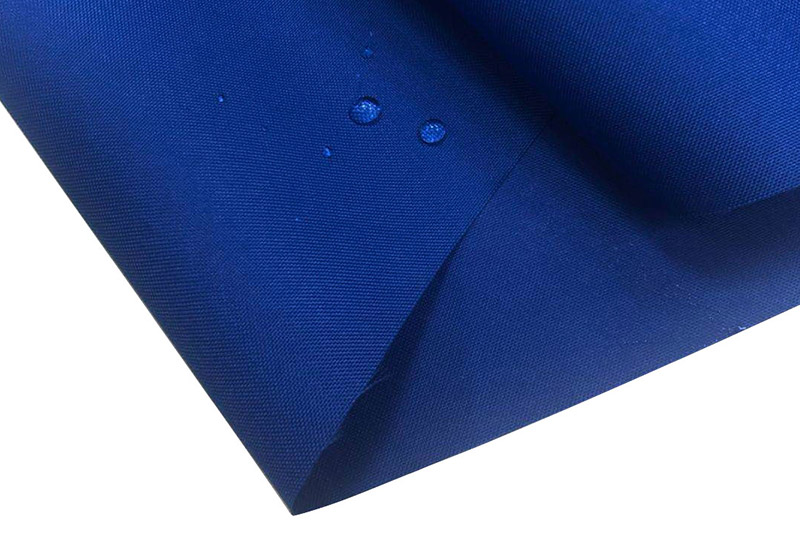

Nylon's wind-resistant properties and ability to accept waterproof coatings make it the go-to choice for protective outerwear. When combined with treatments like polyurethane coating, DWR (durable water repellent) finishes, or laminated waterproof membranes, nylon creates effective barriers against rain, wind, and snow while remaining lightweight and packable.

- Rain jackets and waterproof shells for hiking and outdoor activities

- Windbreakers for running and cycling in breezy conditions

- Insulated jackets using nylon shells over down or synthetic fill

- Ski and snowboard jackets requiring waterproof, breathable performance

- Packable travel jackets that compress into small carry pouches

Intimate Apparel and Hosiery

The smooth, silky texture of certain nylon types makes them ideal for intimate apparel and hosiery production. Nylon's elasticity ensures garments conform comfortably to body contours while maintaining their shape through repeated wear and washing. The fabric's thin profile creates seamless appearances under clothing while providing necessary support and coverage.

- Stockings and pantyhose with excellent stretch and recovery

- Bras and underwear combining comfort with durability

- Shapewear providing firm control and smooth silhouettes

- Lingerie featuring delicate, luxurious aesthetics

- Socks for athletic and everyday wear

Workwear and Professional Garments

Industrial and professional settings benefit from nylon's exceptional durability and resistance to chemicals, oils, and abrasion. Work garments incorporating nylon withstand harsh conditions while maintaining their structural integrity and appearance over extended periods, reducing replacement costs and ensuring worker safety and comfort.

- Cargo pants with nylon reinforcements in high-wear areas

- Coveralls for mechanics and industrial workers

- Aprons resistant to stains and chemicals

- Medical scrubs requiring frequent laundering and sanitization

- Uniforms for outdoor workers needing weather protection

Comparing Nylon Types for Clothing Applications

| Nylon Type | Key Strength | Best Applications | Weight |

| Nylon 6 | Softness, dyeability | Hosiery, lingerie, activewear | Light to medium |

| Nylon 6,6 | Heat resistance, strength | Outdoor wear, workwear | Medium to heavy |

| Ripstop | Tear resistance | Rain jackets, windbreakers | Very light |

| Ballistic | Extreme durability | Reinforcements, tactical gear | Heavy |

| Taslan | Natural feel | Casual jackets, sportswear | Light to medium |

Advantages of Nylon in Clothing Manufacturing

Nylon's dominance in clothing production stems from its unique combination of benefits that few other fabrics can match. The material's exceptional strength-to-weight ratio allows manufacturers to create durable garments without excessive bulk, perfect for modern consumers seeking lightweight, packable clothing. Its resistance to wrinkles means garments maintain a neat appearance throughout the day, reducing the need for ironing and making nylon ideal for travel wear.

The fabric's quick-drying properties prove invaluable for both active wear and travel garments, as items can be washed and dried overnight, ready for next-day use. Nylon's color retention ensures garments maintain their vibrant appearance through countless wash cycles, while its resistance to pilling keeps surfaces smooth and attractive. These combined advantages explain why nylon remains a staple in modern wardrobes across all clothing categories.

Care and Maintenance of Nylon Garments

Proper care extends the life and performance of nylon clothing significantly. Most nylon garments tolerate machine washing in cold to warm water, though checking manufacturer labels ensures appropriate treatment for specific items. Using mild detergents prevents chemical damage to fibers, while avoiding bleach maintains color integrity and fabric strength. Fabric softeners should be avoided on technical nylon garments, as they can coat fibers and reduce moisture-wicking capabilities.

Nylon dries quickly, making air-drying the preferred method that conserves energy and prevents heat damage. If machine drying is necessary, use low heat settings to prevent melting or distortion. Nylon's heat sensitivity requires careful ironing—if needed, use the lowest heat setting with a pressing cloth between the iron and fabric. Store nylon garments away from direct sunlight, as prolonged UV exposure can degrade fibers and cause fading over time.

Environmental Considerations and Sustainable Alternatives

As awareness of environmental impacts grows, the textile industry is developing more sustainable nylon options. Recycled nylon, created from post-consumer waste like fishing nets, carpet fibers, and fabric scraps, offers identical performance to virgin nylon while reducing petroleum consumption and waste. Bio-based nylons derived from renewable resources like castor beans provide another alternative, though production remains limited compared to traditional nylon.

Consumers can minimize environmental impact by choosing garments from manufacturers committed to sustainable practices, properly caring for nylon items to extend their lifespan, and recycling or repurposing garments at end-of-life rather than discarding them. As technology advances, expect increasingly eco-friendly nylon options that maintain the performance characteristics that make this fabric indispensable in modern clothing.

Selecting the Right Nylon for Your Needs

Choosing appropriate nylon fabric depends on your specific requirements, intended use, and performance expectations. For high-intensity athletic activities, opt for lightweight Nylon 6 blends with moisture-wicking treatments that keep you dry and comfortable. Outdoor enthusiasts benefit from ripstop nylon's tear resistance and packability in rain gear and windbreakers. Those seeking everyday comfort in intimate apparel should select soft, fine-denier nylon with excellent stretch properties.

Consider environmental factors when making purchasing decisions, favoring recycled or bio-based nylon options when available. Evaluate care requirements against your lifestyle—busy professionals might prefer easy-care nylon garments that wash and dry quickly. Understanding these different nylon types and their applications empowers you to make informed choices that deliver optimal performance, longevity, and satisfaction in your clothing investments.

English

English 简体中文

简体中文 русский

русский Español

Español