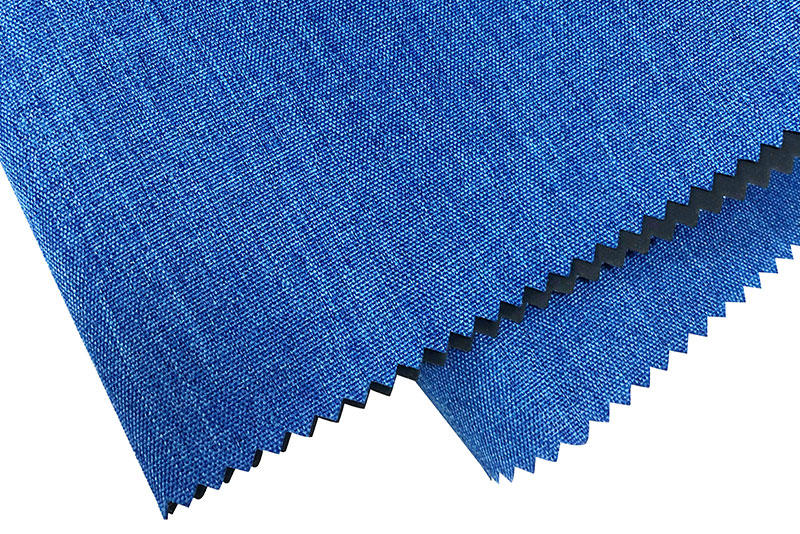

Cationic Fabric polyester waterproof 300D300DCATION-PU

Cationic Fabric

Name polyester waterproof 300D*300D pu coated cation oxford fabric for outdoor furnitures Mate......

See Details-- Steady & Reliable Manufacturer --

Digital Print Ready Fabric is specifically engineered to meet the high-definition requirements of modern sublimation and direct-to-textile printing. Our "Ready for Print" (RFP) Oxford undergoes a specialized scouring and heat-setting process to ensure the fabric is free from oils, waxes, and impurities that could interfere with ink absorption. In the B2B customized gear market, print clarity and color vibrancy are the primary quality benchmarks. This fabric features a high-white point and a flat surface tension that allows for sharp edge definition and deep tonal gradients. Whether you are producing vibrant outdoor banners or personalized promotional backpacks, the chemical stability of our base fabric prevents "ghosting" or color shifting during the heat transfer process. We focus on ensuring dimensional stability, so the fabric does not shrink or warp under the 200°C temperatures required for sublimation. This provides printers with a reliable, consistent canvas that maximizes ink efficiency and produces photorealistic results for high-end branded merchandise.

Name polyester waterproof 300D*300D pu coated cation oxford fabric for outdoor furnitures Mate......

See Details

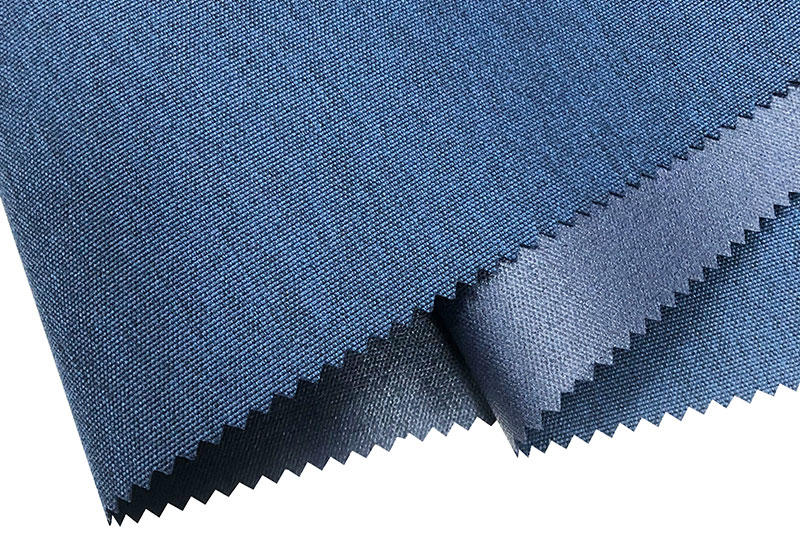

Name 300D*300D CATION POLYESTER OXFORD FABRIC WITH PVC COATING FOR BACKPACK BAGS Material pol......

See Details

Name pu coating 300D cation ripstop polyester oxford fabric wholesale Material polyester ......

See Details

Name 600D*600D*64T CATION POLYESTER OXFORD FABRIC WITH PVC COATED FOR BACKPACK Material polye......

See Details

Name 600D pu coated cation polyester oxford fabric for backpack bags Material polyester Ba......

See Details

Name 600D pu coated cation polyester oxford fabric for backpack bags Material polyester Ba......

See Details| Base Material | 100% PFP (Prepared for Print) Polyester |

|---|---|

| White Point | CIE Whiteness 145-155 |

| Ink Type | Sublimation, UV, Latex |

| Heat Stability | <1.5% Shrinkage at 210°C |

| Surface | Smooth Semi-Matte |

Handle with clean gloves to prevent oil transfer before printing. After printing, the fabric can be washed in cold water. Avoid high-heat tumble drying which may affect the print's vibrancy over time.

The core advantage of our Print Ready Fabric is its superior ink-holding capacity. Standard Oxford fabrics often suffer from ink bleeding or "wicking," where the color spreads along the fibers, resulting in blurry logos. Our fabric is treated with a specialized receptive layer that locks the dye into the fiber immediately upon contact. Furthermore, our strict heat-setting protocol ensures that the fabric width remains consistent across every roll, which is critical for high-speed automated printing lines. By choosing a specialized PFP base, manufacturers can reduce ink consumption by up to 15% while achieving a 20% increase in color saturation compared to standard off-the-shelf textiles.

Welcome friends from all walks of life to visit, guide and business negotiation.

+86-571-22917799

No.88 Yinxin Rd.,Yaqian Town,Hangzhou City, Zhejiang, China.