Polyester Oxford fabric has become a widely recognized material in the textile and manufacturing industries due to itsdurability, water resistance, and wide range of applications. Known for its characteristic basketweave texture, this fabric is used in countless products, including backpacks, outdoor gear, luggage, tents, workwear, and more. Its combination of affordability and resilience makes it a favorite among both manufacturers and consumers.

In this article, we’ll explore what Polyester Oxford fabric is, how it’s made, its key features, common applications, and why it remains a reliable choice for heavyduty textile needs.

What Is Polyester Oxford Fabric?

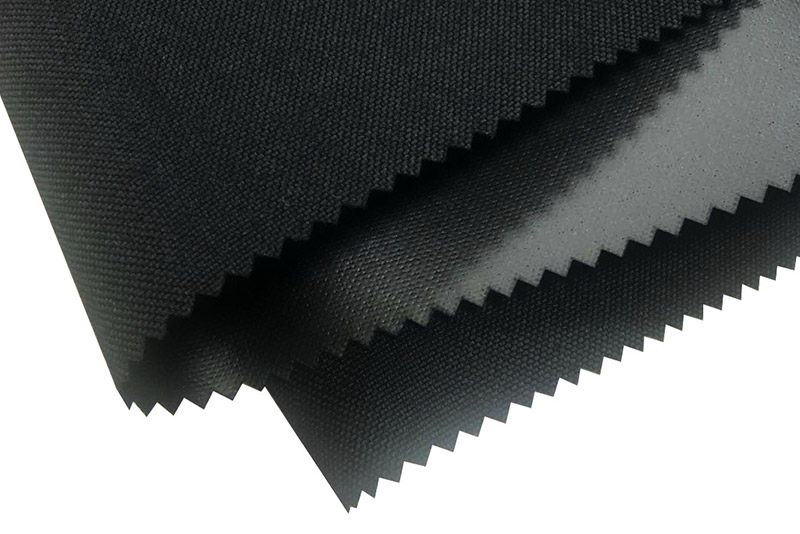

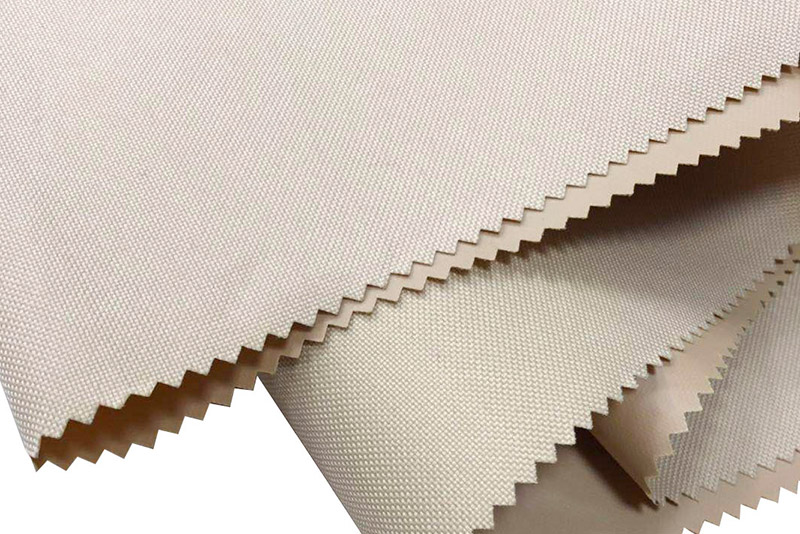

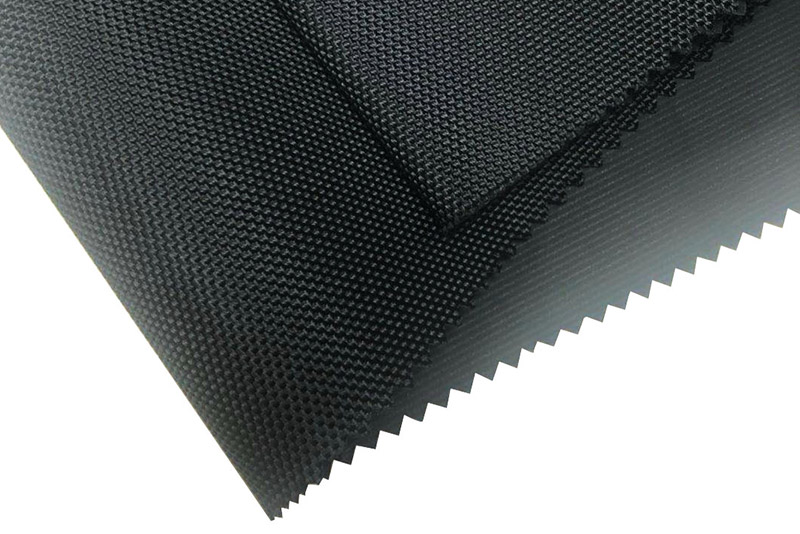

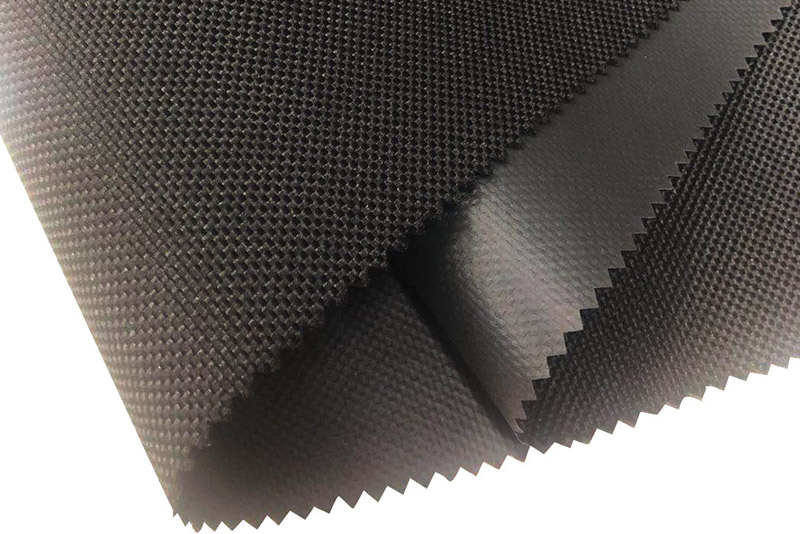

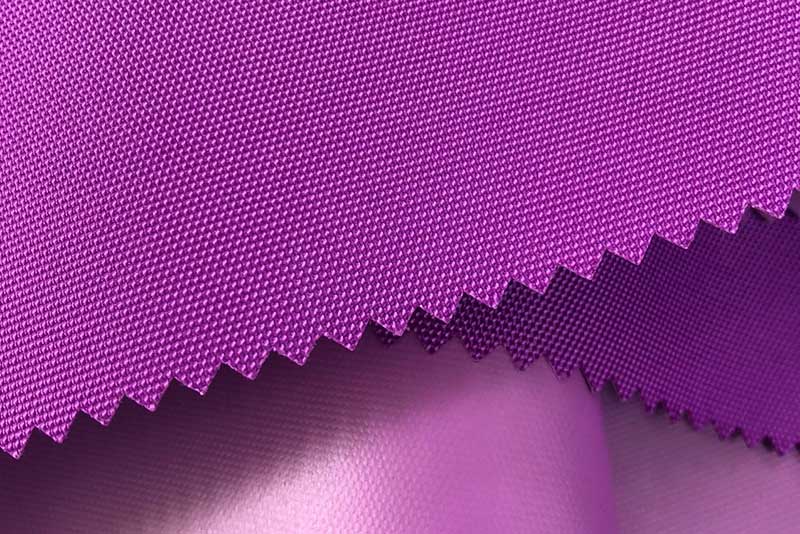

Polyester Oxford fabric is awoven textile made primarily from polyester fibers, often designed using aplain or basket weave structure. The term "Oxford" originates from traditional Oxford cloth, a cotton fabric first created for shirts. However, modern Oxford fabric—particularly the polyester version—has evolved into a muchstronger, coated material suitable for technical and rugged uses.

The fabric is typically woven in a way that creates a slightly textured appearance, giving itincreased strength and resistance to tearing. It is often coated with polyurethane (PU), PVC, or other waterproof treatments to enhance its performance, especially in outdoor environments.

How Is Polyester Oxford Fabric Made?

The manufacturing process starts withpolyester yarns, which are synthetic fibers made from petroleumderived polymers. These fibers are:

1.Spun into yarn

2.Woven into fabric using the Oxford weave pattern (a type of basket weave)

3.Dyed and treated with chemical coatings for waterproofing, UV resistance, or flame retardancy, depending on the intended use

The weaving structure and the denier (a measurement of fiber thickness, such as 210D, 600D, 1680D) play a major role in determining the fabric’sweight, texture, and strength.

Key Features of Polyester Oxford Fabric

Polyester Oxford fabric offers several desirable qualities:

Durability: Known for excellent wear resistance, making it suitable for heavy use and outdoor exposure.

Water Resistance: Many versions are treated with a waterproof coating to repel moisture and rain.

Tear and Abrasion Resistance: The weave pattern and synthetic fibers make the fabric resistant to punctures and fraying.

Lightweight: Despite its toughness, the fabric is relatively light, which makes it ideal for portable products like bags and tents.

UV Resistance: With proper treatment, the fabric resists fading and degradation from sun exposure.

CostEffective: Polyester is less expensive to produce compared to natural fibers like cotton or wool, making the fabric affordable.

Easy to Clean: Its smooth surface and synthetic makeup allow for easy wiping and maintenance.

Common Applications of Polyester Oxford Fabric

Due to its strength and adaptability, Polyester Oxford fabric is used in a variety of industries and products:

1.Luggage and Bags

Backpacks, suitcases, laptop sleeves, and duffel bags are often made from 600D or 1680D Oxford fabric. It offers the toughness needed for travel while maintaining a lightweight feel.

2.Outdoor Gear

Tents, camping chairs, hammocks, and sleeping bag covers use waterproof Oxford fabric to withstand harsh weather conditions and frequent use.

3.Apparel and Workwear

Some uniforms, jackets, and raincoats feature Oxford fabric for outer layers, offering protection against wind, rain, and abrasion.

4.Furniture Covers

Used for patio furniture covers, BBQ grill covers, and car covers due to its ability to shield from UV rays, rain, and dust.

5.Pet Accessories

Leashes, collars, pet beds, and carrier bags often incorporate this fabric because of its durability and ease of cleaning.

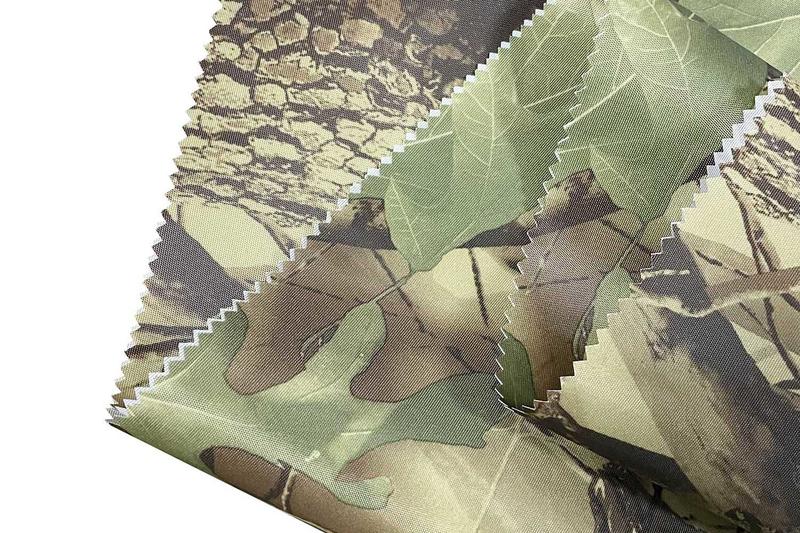

6.Advertising and Event Materials

Portable canopies, banners, and promotional tents use heavyduty Oxford fabric because it is strong, waterproof, and printable.

Why Choose Polyester Oxford Fabric?

Polyester Oxford fabric is popular not only because of its durability, but also because it offersa balance between performance and affordability. Compared to nylon, which is slightly stronger and more expensive, polyester Oxford is often amore economical solution for applications where extreme performance isn’t required.

Additionally, polyester hasbetter UV and mildew resistance than nylon, making it a better choice for longterm outdoor use. Itslow moisture absorption means it dries quickly and resists mold, while thecoated versions can hold up under rain or spills.

Environmental Considerations

While polyester is a synthetic and nonbiodegradable material, the industry has seen a rise in the use ofrecycled polyester (rPET) in Oxford fabric production. This recycled fiber is made from postconsumer plastic bottles and waste, offering a more sustainable alternative while maintaining the same physical properties.

Proper use and care of polyester Oxford fabric products can also extend their lifespan, reducing the frequency of replacement and overall environmental impact.

Maintenance Tips

Polyester Oxford fabric is relatively lowmaintenance, but here are some care suggestions to ensure longevity:

Wipe regularly with a damp cloth to remove dirt and stains.

Avoid harsh detergents that could degrade waterproof coatings.

Air dry instead of using highheat dryers, which can warp coatings.

Store in a dry, cool place to prevent mold or odor development.

Conclusion

Polyester Oxford fabric is apowerful combination of strength, water resistance, and affordability, making it ideal for countless everyday and industrial uses. Whether it's shielding outdoor furniture from the elements, keeping your gear dry on a camping trip, or holding your essentials in a rugged backpack, this fabric has proven its value across decades.

Thanks to itsevolving coatings, ecofriendly innovations, and versatile applications, Polyester Oxford fabric continues to be a smart and reliable choice in textile manufacturing and design.

English

English 简体中文

简体中文 русский

русский Español

Español