FDY Polyester Oxford Fabric vs. Nylon Oxford Fabric: A Comprehensive Comparison

Introduction

Oxford fabrics are widely used in luggage, backpacks, tents, and outdoor gear due to their durability, water resistance, and lightweight properties. The two most common types are FDY polyester Oxford fabric and nylon Oxford fabric, each offering distinct advantages depending on the application.

This article provides a detailed comparison between FDY polyester Oxford fabric and nylon Oxford fabric, examining their material properties, strength, water resistance, cost, and best-use scenarios.

1. Material Composition & Manufacturing Process

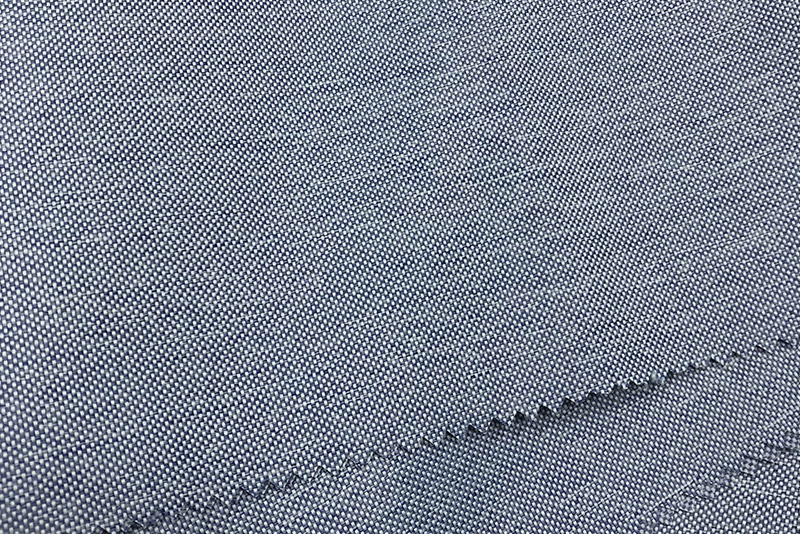

A. FDY Polyester Oxford Fabric

Base Material: 100% polyester (FDY means the yarn is fully stretched for higher strength).

Weaving Method: Plain or basket weave, often with a waterproof coating (PU or PVC).

Key Features:

High tensile strength

Excellent abrasion resistance

UV and mildew resistance

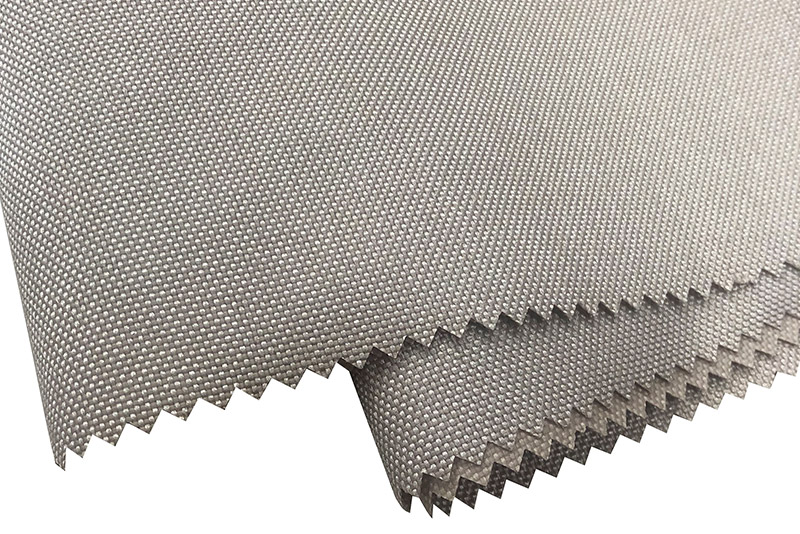

B. Nylon Oxford Fabric

Base Material: Nylon 6 or Nylon 66 (more elastic than polyester).

Weaving Method: Similar weave styles but with a softer hand feel.

Key Features:

Higher tear resistance

Better elasticity and flexibility

Superior water resistance (when coated)

2. Performance Comparison

A. Strength & Durability

Property FDY Polyester Oxford Nylon Oxford

Tensile Strength Very high Slightly lower but more flexible

Abrasion Resistance Excellent Good (but may pill over time)

Tear Resistance Good Better (due to nylon’s elasticity)

Conclusion:

FDY polyester is stronger under constant load (better for heavy-duty bags).

Nylon resists tearing better (ideal for backpacks and outdoor gear).

B. Water Resistance

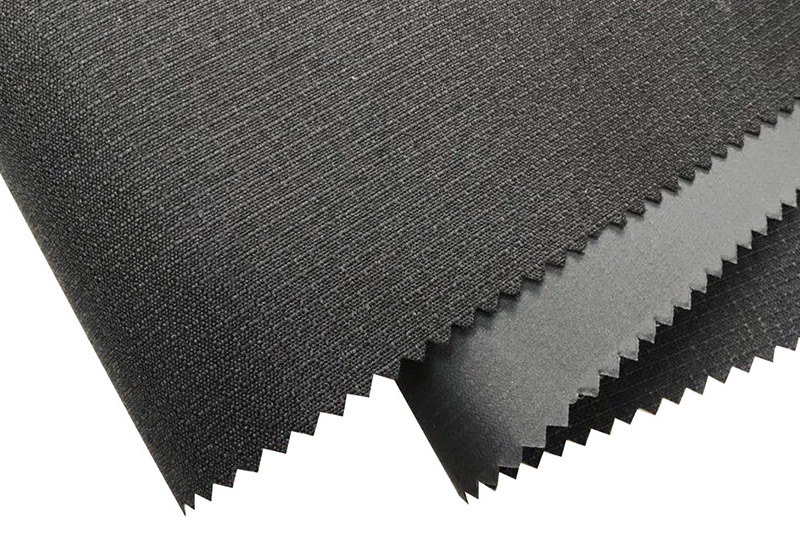

Both fabrics can be PU or PVC-coated for waterproofing.

Nylon absorbs less water when uncoated, making it slightly better in wet conditions.

Polyester is more hydrophobic but may require thicker coatings for full waterproofing.

C. Weight & Flexibility

Nylon is lighter and more flexible, making it comfortable for wearable gear.

Polyester is stiffer, providing more structure for luggage and rigid bags.

D. UV & Chemical Resistance

Polyester has better UV resistance, making it ideal for outdoor products (e.g., tents, awnings).

Nylon degrades faster under sunlight unless treated with UV inhibitors.

Polyester resists oils and chemicals better than nylon.

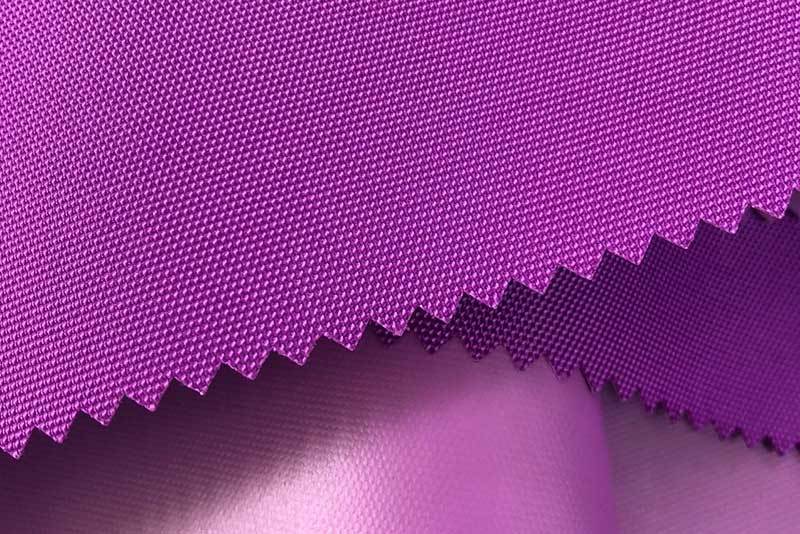

E. Color Fastness & Aesthetics

Polyester holds dye better, resulting in brighter, longer-lasting colors.

Nylon has a softer sheen, often preferred for premium luggage and fashion backpacks.

3. Cost Comparison

Factor FDY Polyester Oxford Nylon Oxford

Material Cost Lower (more affordable) Higher (premium price)

Production Cost Lower (easier to dye & coat) Higher (requires more processing)

Long-Term Value Good for budget products Better for high-end, long-lasting gear

Economic Considerations:

Polyester is cost-effective for mass-produced items (e.g., school bags, promotional totes).

Nylon is preferred for premium products (e.g., travel backpacks, military gear).

4. Common Applications

A. FDY Polyester Oxford Fabric Uses

Luggage & suitcases (durable, structured)

Tents & outdoor covers (UV-resistant)

Workwear & tool bags (abrasion-resistant)

Promotional bags (cost-efficient)

B. Nylon Oxford Fabric Uses

High-end backpacks (lightweight, flexible)

Military & tactical gear (tear-resistant)

Fashion accessories (softer texture)

Waterproof jackets & covers (better water repellency)

5. Maintenance & Longevity

Factor FDY Polyester Oxford Nylon Oxford

Washability Easy (resists wrinkles) May retain odors, needs gentle washing

Drying Time Fast (low water absorption) Slower (absorbs more water)

Longevity Excellent (resists wear) Good (but may degrade with UV exposure)

Care Tips:

Polyester: Machine washable, quick-drying.

Nylon: Use mild detergent, avoid high heat.

6. Which One Should You Choose?

Choose FDY Polyester Oxford Fabric If:

You need high strength and abrasion resistance.

Budget-friendly production is a priority.

The product will be exposed to UV rays or chemicals.

Choose Nylon Oxford Fabric If:

You need lightweight, flexible, and tear-resistant material.

Water resistance and a premium feel are important.

The product is for high-end or outdoor performance gear.

7. Future Trends in Oxford Fabrics

Recycled polyester & nylon (eco-friendly options).

Nanotech coatings for enhanced waterproofing.

Hybrid blends (combining polyester and nylon benefits).

Conclusion

Both FDY polyester Oxford fabric and nylon Oxford fabric have unique strengths:

| Factor | FDY Polyester Wins | Nylon Wins |

|---|---|---|

| Strength | Higher tensile strength | — |

| Tear Resistance | — | More flexible & durable |

| Water Resistance | — | Better when uncoated |

| Cost | More affordable | More expensive |

| UV Resistance | Superior | Requires treatment |

Final Recommendation:

For heavy-duty, cost-effective products → FDY polyester Oxford fabric.

For lightweight, high-performance gear → Nylon Oxford fabric.

English

English 简体中文

简体中文 русский

русский Español

Español