In the ever-evolving world of technical textiles, one material stands out for its unbeatable combination of strength, versatility, and cost-efficiency: DTY Polyester Oxford Fabric. Widely used in luggage, outdoor gear, industrial applications, and protective clothing, this advanced fabric has become a go-to solution for manufacturers seeking a reliable, high-performance textile that can withstand the toughest conditions.

But what exactly is DTY Polyester Oxford Fabric? Why is it preferred over standard polyester fabrics? And how is it revolutionizing industries from travel accessories to military equipment? In this comprehensive, SEO-optimized article, we’ll explore the science behind this innovative material, its manufacturing process, key benefits, diverse applications, and why it’s shaping the future of durable textiles.

What Is DTY Polyester Oxford Fabric?

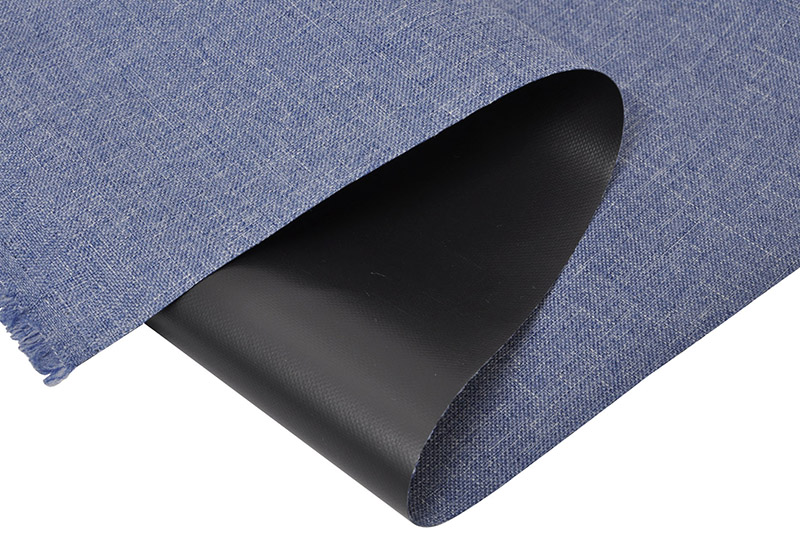

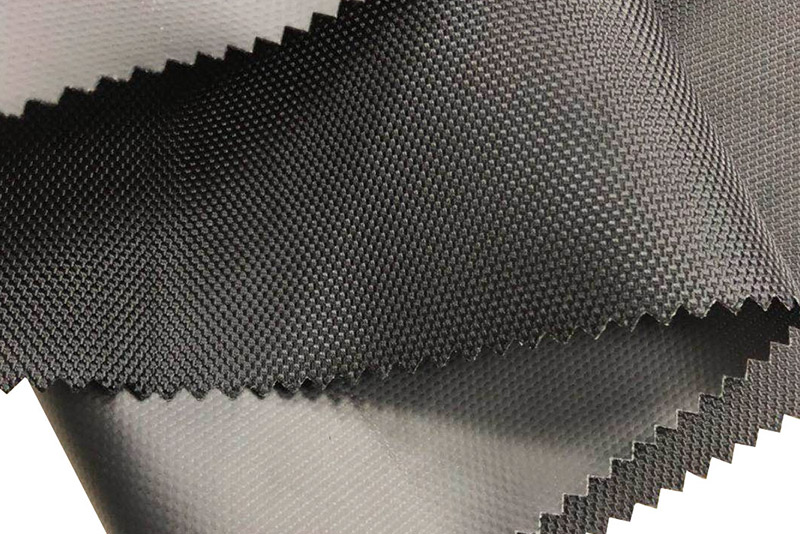

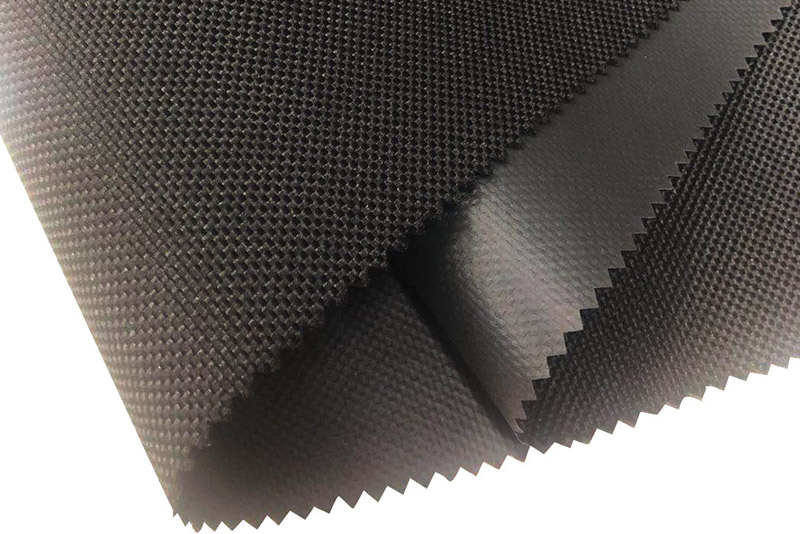

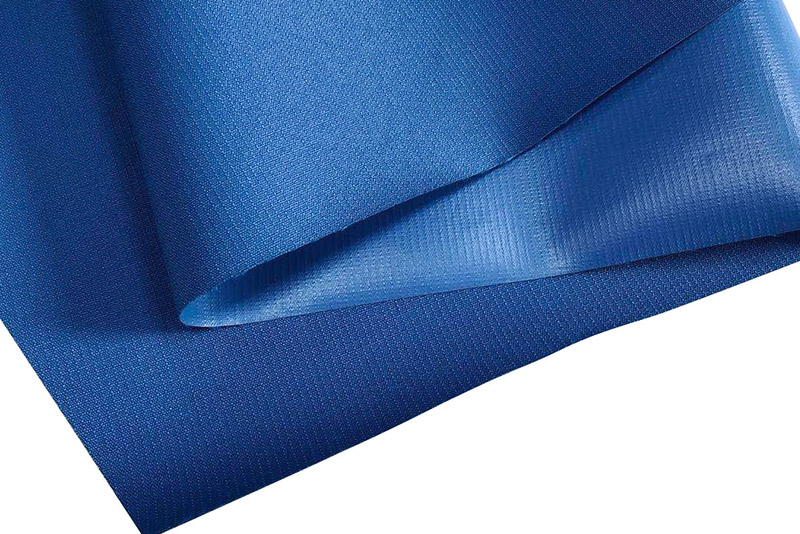

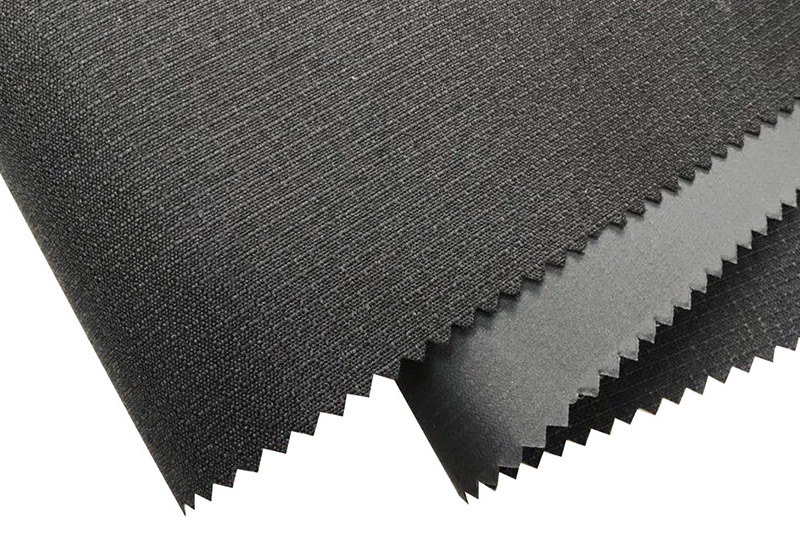

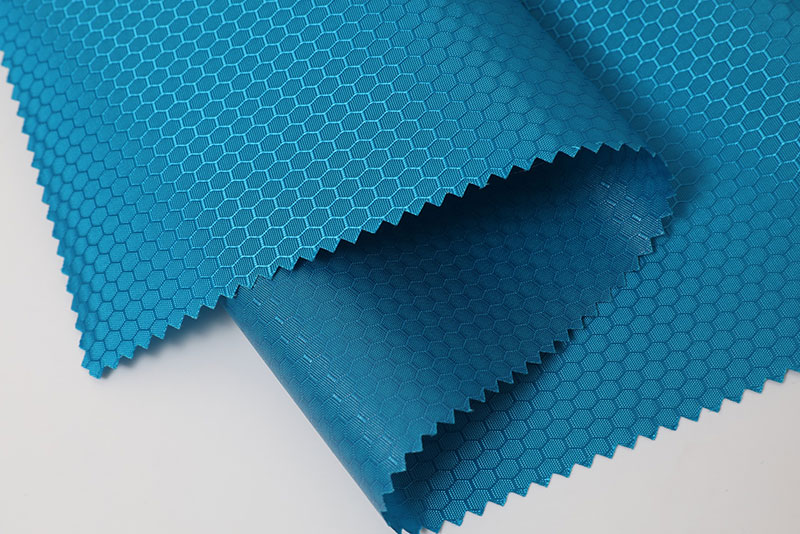

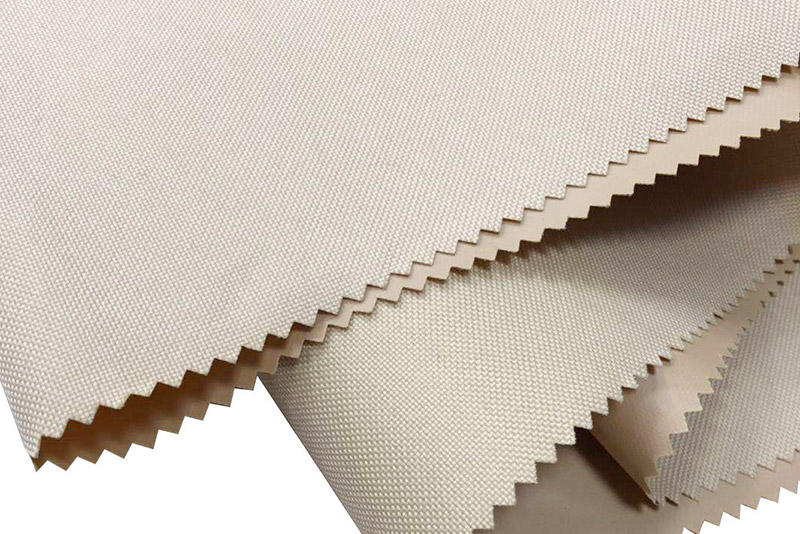

DTY Polyester Oxford Fabric is a high-strength woven textile made from Drawn Textured Yarn (DTY) polyester, structured in a distinctive Oxford weave pattern. The term "Oxford" refers to the fabric’s unique basket-like weave, where two fine warp yarns are interlaced with one heavier weft yarn, creating a durable, slightly textured surface with excellent abrasion resistance.

The "DTY" component refers to the type of polyester yarn used—Drawn Textured Yarn—which undergoes a special drawing and texturing process to enhance its bulk, elasticity, and softness while maintaining high tensile strength. Unlike FDY (Fully Drawn Yarn), DTY has a crimped, fluffy structure that improves fabric coverage, comfort, and drape, making it ideal for applications that require both toughness and a degree of flexibility.

The result is a fabric that is lightweight yet extremely durable, resistant to tearing, UV exposure, and moisture, and capable of withstanding repeated use in demanding environments.

How Is DTY Polyester Oxford Fabric Made?

The production of DTY Polyester Oxford Fabric involves several precision-engineered steps:

Yarn Production: Polyester chips are melted and extruded into filaments, which are then drawn (stretched) and textured using air jets or mechanical crimping. This process gives DTY its characteristic bulk and resilience.

Weaving: The DTY yarn is woven in an Oxford pattern—typically a 2x1 or

2x2 basket weave—on high-speed looms. This structure enhances fabric stability and reduces fraying.

Coating and Finishing: The fabric is often coated with PU (polyurethane), PVC, or waterproofing agents to improve water resistance, durability, and windproof qualities. Additional treatments may include UV protection, anti-mildew, flame retardancy, or anti-static finishes.

Dyeing: High-temperature dyeing ensures deep color penetration and excellent colorfastness, even after prolonged sun exposure or washing.

The final product is a tightly woven, dimensionally stable fabric with a soft hand feel, excellent tear strength, and long-lasting performance.

Key Advantages of DTY Polyester Oxford Fabric

One of the main reasons DTY Polyester Oxford Fabric has gained widespread popularity is its exceptional balance of performance and practicality.

Superior Durability

The Oxford weave and high-tenacity DTY yarn make this fabric highly resistant to abrasion, tearing, and punctures—ideal for products that face daily wear and rough handling.

Lightweight and Flexible

Despite its strength, the fabric remains lightweight, making it perfect for travel gear, backpacks, and sportswear where comfort and mobility are essential.

Water and Weather Resistance

With proper coating, DTY Oxford fabric offers excellent protection against rain, humidity, and UV rays, ensuring long life even in harsh outdoor conditions.

Breathability and Comfort

Compared to heavier canvas or vinyl materials, DTY Polyester Oxford allows for better air circulation, enhancing comfort in clothing and gear.

Cost-Effective Production

Polyester is more affordable than natural fibers like cotton or leather, and DTY yarn’s high coverage reduces material waste during cutting and sewing.

Easy to Clean and Maintain

The fabric resists stains and can be wiped down or machine washed without losing shape or color—perfect for consumer and industrial use.

Customizable Appearance

Available in a wide range of colors, weights (from 150D to 600D), and finishes (matte, glossy, embossed), DTY Oxford fabric can be tailored to meet brand aesthetics and functional needs.

Common Applications of DTY Polyester Oxford Fabric

The versatility of DTY Polyester Oxford Fabric makes it suitable for a broad spectrum of industries:

Luggage and Travel Bags

Used in suitcases, duffel bags, and carry-ons for its scratch-resistant surface and lightweight strength. The fabric maintains its shape and appearance after repeated use.

Backpacks and Outdoor Gear

Ideal for hiking backpacks, school bags, and tactical gear due to its ruggedness and water-repellent properties. Often combined with reinforced stitching and padding for added protection.

Tents and Shelter Materials

Provides reliable protection from wind and rain in camping tents, emergency shelters, and pop-up canopies. Its UV resistance ensures long-term outdoor use.

Protective Clothing and Workwear

Used in industrial uniforms, coveralls, and rainwear for its durability and chemical resistance. Flame-retardant versions are available for high-risk environments.

Automotive and Marine Covers

Car covers, boat covers, and trailer tarpaulins benefit from the fabric’s ability to resist moisture, mildew, and UV degradation.

Military and Tactical Equipment

Favored for backpacks, holsters, and field gear due to its low visibility (in camouflage prints), strength, and resistance to environmental stress.

Furniture and Upholstery

Lightweight yet durable, it’s used in outdoor furniture, pet beds, and foldable seating where water resistance and easy maintenance are key.

Promotional and Branded Merchandise

Companies use DTY Oxford fabric for branded tote bags, event gear, and corporate gifts—durable enough to last and professional in appearance.

Why Choose DTY Over Other Polyester Yarns?

While FDY (Fully Drawn Yarn) offers high strength, it lacks the softness and bulk of DTY. In contrast, DTY provides:

Better fabric coverage with fewer yarns

Improved comfort due to its textured, slightly elastic nature

Enhanced insulation from trapped air in the crimped fibers

Greater aesthetic appeal with a softer drape and reduced sheen

This makes DTY Polyester Oxford Fabric particularly suitable for end products that require a balance of toughness and user comfort.

Sustainability and Eco-Friendly Innovations

As environmental responsibility becomes a priority, manufacturers are developing sustainable versions of DTY Polyester Oxford Fabric:

Recycled DTY Polyester (rPET): Made from post-consumer plastic bottles, reducing landfill waste and carbon footprint.

Eco-Coatings: Water-based PU coatings replace solvent-based alternatives, minimizing VOC emissions.

Biodegradable Treatments: Research is underway to develop biodegradable waterproofing layers.

OEKO-TEX® Certified Fabrics: Ensures the fabric is free from harmful substances, making it safe for skin contact.

Many global brands now specify GRS (Global Recycled Standard)-certified DTY Oxford fabric in their sustainability reports, reflecting a growing shift toward circular textile economies.

Care and Maintenance

To extend the life of products made from DTY Polyester Oxford Fabric:

Clean with mild soap and water; avoid harsh chemicals.

Air dry—do not tumble dry at high heat.

Store in a dry, ventilated area to prevent mold.

Reapply waterproofing spray periodically for outdoor gear.

With proper care, items made from this fabric can last for years, even under heavy use.

The Future of DTY Polyester Oxford Fabric

Innovation continues to enhance the performance of this already impressive material:

Smart Textiles: Integration with conductive fibers for wearable tech applications.

Self-Cleaning Surfaces: Nanocoatings that repel dirt and water.

3D-Knitted Oxford Panels: Reducing seams and waste in production.

Digital Printing: Allowing for high-resolution, customizable designs without compromising durability.

As demand grows for sustainable, high-performance materials, DTY Polyester Oxford Fabric is poised to remain a leader in the technical textile industry.

Conclusion

DTY Polyester Oxford Fabric is more than just a strong, water-resistant textile—it’s a smart, adaptable solution for modern manufacturing challenges. From rugged backpacks and weatherproof tents to industrial workwear and branded merchandise, its unique blend of durability, comfort, and cost-efficiency makes it a top choice across industries.

With advancements in recycling, coating technology, and smart textiles, the future of DTY Oxford fabric is not only durable but also sustainable and innovative. Whether you're a product designer, brand owner, or manufacturer, choosing DTY Polyester Oxford Fabric means investing in quality, longevity, and performance.

English

English 简体中文

简体中文 русский

русский Español

Español